Small Laser Cutting Job Shops Leverage Quoting Software to Compete with Bigger Players

ToolBox from Tempus Tools has been designed by professionals with decades of experience in the laser cutting industry, and has a user-friendly interface so that it can be setup and run by just about anyone in the company.

Posted: June 5, 2024

Smaller metal fabrication and laser cutting job shops are having to face increasingly sophisticated opposition from big players that have changed the game and nearly eliminated all the friction of ordering custom parts.

Small job shops can still win in the customer service department, though, says Tempus Tools North American sales representative, Jackson Barry.

“Customer service is a key differentiator. By taking on more complex projects, and providing faster turnaround times, the competitive advantage is with the smaller players,” he says.

“However, if pricing is inaccurate or inconsistent, or if processes are sloppy, it can turn customers right off – and rightly so!”

Jackson works with the North American arm of global laser cutting quoting software experts, Tempus Tools, the creators of ToolBox.

“With our cloud-based laser cutting quoting software, ToolBox, job shops can be nimble, see the status of their jobs at a glance, dial in their pricing, and project an image of professionalism that can inspire their customers and elevate the rest of their organisation,” he adds.

Turning Hours into Seconds

For an industry where customer service is key, the time taken to respond to quotes can often mean the difference between winning and losing a particular job.

“Small shops typically rely on pen and paper or simple spreadsheet calculations to do their estimating. This process is very time-consuming and inconsistent. They have to fiddle with drawings, extract parts from assemblies or crowded files, run them through their nesting software, or manually calculate material costs and cycle times,” says Jackson.

“By using ToolBox to generate accurate laser cutting quotes, this process can be done in seconds, instead of taking hours – with additional benefits along the way.”

ToolBox has been designed by professionals with decades of experience in the laser cutting industry, and has a user-friendly interface so that it can be setup and run by just about anyone in the company.

“Small shops find that we solve a bunch of problems for them in a simple and inexpensive package, with plans that start as low as $75/month USD,” says Jackson.

Added Value

Additional benefits of using ToolBox include:

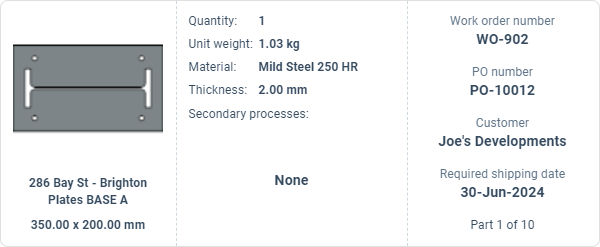

- Crisp, professional, branded quotes.

- Thumbnails of all the parts.

- Automatically generated work orders, packing slips, and production labels to assist with managing the shop floor.

- The ability to instantly quote 2D parts and 3D assemblies, tubing, bending, and finishing straight from a file upload.

- Integration with programs like QuickBooks and Xero to link ToolBox with existing invoicing processes.

- Clear visibility into prior orders, allowing for repeat orders to be duplicated in seconds, without having to dig through computer files or emails.

- Marketing opportunities like the Web Store online quoting portal.

“Additionally, conventional quoting approaches often do not take into account all of the costs to run a job and a business (setup, secondary operations, direct and indirect operating costs, material mark ups, and so forth). Small shops need to streamline, eliminate the busy work, reduce stress, and make room to bring in more projects, and this is where ToolBox can add further value,” says Jackson.

“On top of that, our development team is consistently working on new features, based on customer feedback, to add even more value to ToolBox users.”

“So for any smaller job shops, I’d encourage them to try ToolBox on a free no-obligation 14-day trial that can be used for generating and sending actual quotes to customers and taking online web orders on day one. And we are here for support, demonstrations, and any further help job shops might need.”

To learn more, please click here.