Smart Sustainability

The metalworking industry is at a crossroads. Fortunately, supplier partners are leading the way in supporting shops as they navigate the road to implementing smart and sustainable manufacturing practices.

Posted: June 11, 2024

There is considerable hype around the topic of sustainability in the U.S. manufacturing sector, accompanied by a barrage of buzz words — circular economy, closed loop, carbon neutral, carbon footprint, industrial ecosystem, digitalization of processes — and so on.

According to a recent report by Rockwell Automation, there are any number of motivations behind pursuing sustainable manufacturing initiatives: improving efficiencies; addressing issues before they become problems; competitive advantage; fostering a collaborative environment; and supplier and customer demands, among other factors.

For metalworkers, the message is clear: there is no time to waste when it comes to implementing sustainable practices into their processes because resources are finite, and energy is expensive. Efforts range from reducing energy to recycling and repurposing to utilizing digitalization technologies and eco-friendly machines.

Metalworking shops have been and will continue to collaborate with their trusted supplier partners and others to make meaningful gains in accomplishing sustainable manufacturing practices. Industry leaders have been designing and manufacturing machines, equipment and technologies to assist your shop in the successful pursuit of sustainability.

Electric Automated Bending System Achieves High-precision Processing

AMADA AMERICA INC.’s (Buena Park, CA) EGB 1303 ARse is an eco-friendly electric automated bending system that achieves precise, high speed unmanned productivity. The electrified D-axis and crowing axis mean no need to exchange and dispose of oil. The machine reduces standby power by 50% when it is idling. The independent crowning improves longitudinal accuracy.

The system’s automated tool setup, gripper exchange, bending, and stacking enables 24/7 operation. The system’s 6-axis robot achieves high-precision processing of high-mix, low-volume parts. Its AMNC 4ie control enables efficient operation for operators of all skill levels, operating on voice commands to request and change bend information. The portable HMI tablet allows operators to view bend information away from the control.

The system’s automated tool changer loads complex tool layouts within minutes and is ideal for variable lot sizes and for the seamless introduction of rush jobs.

The EGB 1303 ARse features a three-finger backgauge, which ensures stable positioning of asymmetrical workpieces. The Bi-S II automatically measures and corrects the angle up to 85% faster than the Bi-S.

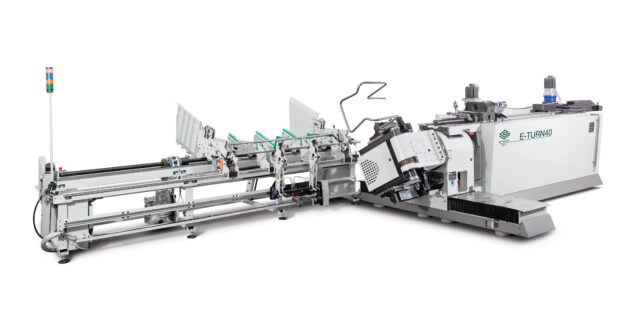

All-electric Tube Bender Offers 80% Savings Compared to Hydraulic Bending Machines

BLM Group’s (Novi, MI) all-electric E-TURN offers reduced power consumption, typically offering 80% savings as compared to conventional hydraulic bending machines. Maintenance is also reduced due to simplified cabling and components.

The E-TURN was created to meet the growing market demand for bending medium-to-small batches of complex, multiple shape tubular components of high-quality material. It is particularly well-suited for complex parts without straight stretches between bends.

E-TURN is offered in different sizes for tubes up to 52 mm diameter and is used in the furniture, automotive, motorcycle, aeronautic and plant engineering sectors. Due to its flexibility and speed, it can be used in all sectors.

A key differentiator of the E-TURN is the VGPNext programming and 3D simulation software. By simply inputting the component bend coordinates, the complete bending program is graphically simulated, highlighting potential collision risks and producing the optimal working cycle. Component feasibility is checked virtually, eliminating the need for prototype tooling or physical testing on the machine. Unloading of the finished component is also automatically managed by VGPNext, with the 180° head rotation allowing the component to be unloaded in the position required.

The E-TURN is available in four sizes capable of handling maximum tube O.D. capacity ranging from 30 mm-x-2 mm (1.18”-x-0.079”) up to 50.8 mm-x-1.5 mm (2”-x-0.059”). Depending on the system, the E-TURN offers a minimum bending radius of 25 mm-to-35 mm and a maximum bending radius of 150 mm-to-165 mm.

Achieve Sustainability Goals with Electric Multidirectional Forklift

Combilift’s (Annahagh, Monaghan, Ireland) Combi CB155E is part of Combilift’s ever growing range of electric models that offer powerful performance, extensive battery life and unrivalled ergonomics. It is the shortest 15,500 lb. capacity counterbalance truck on the market while also benefitting from multidirectional ability, enabling space saving handling of both long and bulky loads.

Design features include large super-elastic tires and a compact wheelbase. The machine benefits from a small footprint as well as exceptional maneuverability meaning that it can easily move bulky loads. The independent electric traction provides all front and rear drive wheels with 100% traction control. This negates the need for differential lock on slippery surfaces and significantly reduces long load momentum twisting when travelling sideways. Each electric drive incorporates parking and regenerative dynamic braking for power efficiency. Roll-out access for major electrical components also simplifies maintenance tasks.

This mix of next-gen performance, extensive battery life and exceptional ergonomics combined with all the advantages of the Combi-CB range, makes this the most powerful compact electric multidirectional forklift on the market. “The increased capacities that we are offering in our electric range will answer the demand for ever more powerful products which at the same time help companies to achieve their aims for more sustainable operations,” said Combilift CEO and co-founder Martin McVicar.

Fully Electric Plate Roller can Decrease Operating Costs by up to 60%

Davi Inc.’s (Addison, Texas) e-POWER all-electric plate roll is a 9-axis machine with dedicated inverters and actuators at each axis point. Unlike hydraulic machines, all e-POWER’s axes operate independently and simultaneously to provide maximum speed and torque regardless of how many axes are in use. The ability to operate multiple axes simultaneously increases throughput with cycle times that are 40% faster than hydraulic machines.

With a positioning accuracy more than twice that of conventional rolling machines, e-POWER provides shops with the highest levels of power and precision. With such precise control and positioning, the machine ensures repeatable and reliable results for a variety of applications, delivering quality.

The e-POWER is highly energy efficient and only consumes power when it is actively rolling for 50% less power consumption than hydraulic machines and 30% less than electric/hydraulic hybrids. Combined with its ability to roll plates 40% faster than hydraulic machines, the e-POWER can decrease operating costs by upwards of 60%.

The plate roller’s design also significantly reduces the need for maintenance. With no hydraulic systems, e-POWER is not plagued by leaking hydraulic seals, clogged lines or the expansion of hoses and fluid due to fluctuations in pressure and temperature. There are also no pistons or valves that are subject to fail. The machine is engineered with fewer components, which decreases the chance of component failure and increases the machine’s durability and precision. What’s more, the inverters and actuators that drive the rollers are easily replaced when needed, as opposed to rebuilding them on site, eliminating repair downtime.

The Role of Tool Holding in Sustainable Machining

The HAIMER Group (Igenhausen, Germany) offers the world’s first hybrid chuck, which combines the vibration-damping properties of a hydraulic chuck with those of a high-precision, high-performance shrink fit chuck. The chuck features a pre-loaded collet system which is laser welded on a shrinking holder. Users are able to make aggressive cuts with the holder and can apply its advantages in applications such as shrinking, drilling, milling and heavy duty machining. With this holder, everything is possible, said Andreas Haimer, president of the HAIMER Group, at EMO 2023, where the hybrid chuck made its debut. The company developed the hybrid chuck during a five year period. Haimer said these hybrid chucks make the machining process more efficient and sustainable. In machining, aside from the materials used, energy efficiencies are one way to measure sustainable manufacturing. The hybrid chuck achieves the highest cutting performance with the lowest vibrations.

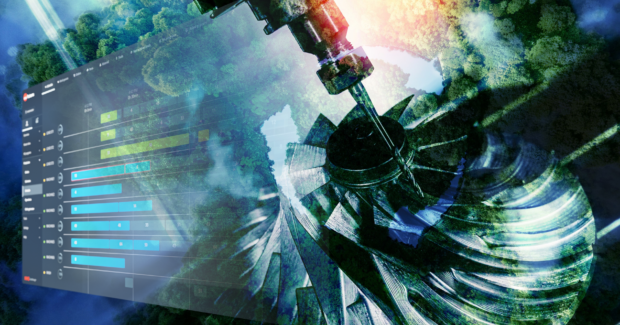

New Sustainability Analyzer Tool Measures and Reduces Carbon Footprint

Sandvik Coromant (Mebane, N.C.), a global leader in metal cutting tools and manufacturing solutions, has launched its new Sustainability Analyzer, an upgraded version of the existing Productivity Analyzer tool. The Sustainability Analyzer enables machining customers to capture, measure and analyze data on their energy consumption and CO2 emissions to support their transition toward more sustainable manufacturing practices.

“As the manufacturing industry works to reduce its carbon footprint, having accurate data on energy usage and emissions is essential to driving meaningful improvements,” said Patrik Eurenius, head of sustainability and EHS at Sandvik Coromant. “Our new Sustainability Analyzer empowers our customers with the insights they need to make informed decisions and take tangible steps toward decreasing their environmental impact.”

The Sustainability Analyzer builds upon Sandvik Coromant’s existing Productivity Analyzer, which has already helped customers save nearly 2 million production hours. The new tool provides detailed reporting on energy consumption per component, annual energy usage and annual CO2 emissions. It leverages data from Sandvik Coromant’s CoroPlus® Tool Guide to calculate these sustainability metrics based on factors such as machine efficiency, local energy prices and material properties.

In a recent test case with a leading automotive manufacturer, the Sustainability Analyzer helped the customer identify a 15% increase in productivity and a 23% reduction in energy consumption per component. Armed with these insights, the customer is now better equipped to make strategic decisions to further reduce its environmental impact.

The Sustainability Analyzer is available to all Sandvik Coromant customers as part of the company’s broader Manufacturing Wellness initiative, which promotes sustainable manufacturing practices.

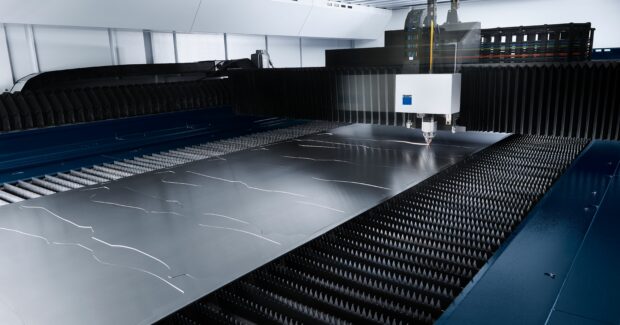

Now Available in North America: Laser Blanking System for Flexible, High-volume Cutting

One of the latest advancements in precision sheet metal fabrication and applications from high-tech company TRUMPF (Farmington, CT) is the TruLaser 8000 Coil Edition, a laser blanking solution designed to boost efficiency and manufacture more sustainably. The TruLaser 8000 Coil Edition can process up to 25 tons of coiled sheet metal from start to finish without any human intervention. It is an attractive option for companies interested in flexible, high-volume solutions for sheet metal fabrication, including automotive suppliers and automakers, electrical cabinet manufacturers, elevator producers, and HVAC manufacturers.

“Compared to conventional laser cutting, the TruLaser 8000 Coil Edition can save up to 1,700 tons of steel a year, which reduces carbon emissions and material costs,” said Grant Fergusson, TRUMPF Inc.’s product manager for TruLaser 2D laser cutting machinery. “The system helps customers with high volumes of medium to large parts improve material utilization and produce more flexibly and sustainably.”

TRUMPF’s new laser blanking system helps companies enjoy the benefits of laser processing, even in high-volume production environments. “Volume manufacturers often use die presses for blanking operations but any modification to these components requires adjusting or even replacing tools, which ultimately costs time and money,” Fergusson added. “Today, many industries are seeing significant reductions in the scale of individual production runs, which makes modifications even more costly and time intensive. The laser allows users to carry out such modifications without another tool, so it’s much easier, faster, cheaper and flexible.”

Coil production enables users to achieve more efficient nesting of parts. Conventional sheets are limited by their four outer edges, which often makes it difficult for production workers to make full use of the entire sheet. Unused sections of the sheet either must be discarded as scrap or melted down. A coil solves this problem by allowing users to nest an almost endless number of parts on the sheet, which reduces material consumption by around 15%.

Compared to conventional 2D laser machines, material flow is different and leads to lower cycle times and new automation opportunities in high-volume production series. The system is designed for thin sheet processing, can handle sheet thicknesses of up to 0.25”, and can be flexibly adapted to any contours.

The production system is fully automated. An innovative system for transporting sheet metal during cutting keeps the material moving quickly through the whole process, with impressive gains in productivity. The new system also incorporates a TruLaser 3040 with TruDisk 8001 and uses many of the tried-and-tested features for which TRUMPF is renowned, including Smart Collision Prevention, which prevents cut parts from tilting and damaging the laser cutting head. The system includes technologies such as EdgeLine Bevel to enable chamfering, and Smart Rerun to save uptime while cutting with reentry techniques.

MMS Software Helps Manufacturers Optimize Their Sustainability Efforts

Fastems (West Chester Township, OH) announces a new version MMS 8.2, the software that controls Fastems’ automation systems, and which helps CNC manufacturers utilize automation to measure, report, and optimize their production sustainability efforts. Users can measure the energy consumption of their NC programs, minimize power usage during machine idle times, and dedicate specific machine tools to process certain metals for high-quality chip recycling. MMS version 8.2 will be available as a new feature and as an upgrade to existing Fastems automation systems beginning this summer.

CNC manufacturers all over the world are looking for ways to measure, report and optimize their sustainability efforts as the demand for sustainability grows. MMS version 8.2 automation control software is developed to help manufacturers in achieving their sustainability goals, especially in the area of high-mix manufacturing.

One of the most important requirements for a manufacturer is to begin measuring and reporting the carbon footprint of their produced parts. MMS 8.2 measures and reports the machine tool energy consumption of each NC program, allowing the manufacturers to calculate the energy usage in part level. The information can also be used to adjust the inefficient NC programs, or running certain parts overnight when the electricity demand is lower.

To minimize unnecessary energy usage, the new “Auto-Power On/Off” function turns machine tools off automatically when there are no planned NC programs to run. With the automatic wake function, the machine starts and warms up before the next NC program start time.

Because metal is a non-renewable and valuable resource, recycling is extremely important to sustainability efforts. MMS 8.2 comes with a material-dedicated feature that allows users to route jobs with specific material to specific machine tools. This way, high-quality chips can be easily separated and recycled.

CERATIZIT: Tooling a Sustainable Future

CERATIZIT, headquartered in Mamer, Luxembourg, is well on its way to being a leader in sustainability in the carbide and cutting tool industry by 2025. The increases in recycling and other initiatives will assist the company in reaching carbon neutrality by 2025. To that end, the company’s Reutte, Austria, production facilities will run on 50% green hydrogen starting in 2025. Additionally, since the beginning of 2023, the company has been manufacturing its products using more than 99% green electricity from renewable sources.

CERATIZIT has established four levels of action toward its goals, including reducing CO2 emissions, and improving circularity in its first step of action. Regarding circularity, the company has implemented efficiencies regarding materials (recycled carbide and tool regrinding programs) and resources used in the production process. Regarding CO2 reductions, the company is focused utilizing sustainable products and technological innovations.

A highlight of CERATIZIT’s sustainability initiatives is its recycled cemented carbide grade product family called upGRADE, which includes two grades at the moment. With mine-to-market infrastructure in place, CERATIZIT can better control the process in maximizing the production of recycled carbide. The first grade, the CT-GS20Y product, debuted in 2022 in the manufacture of the company’s rods. The premium grades feature an 80% lower Product Carbon Footprint (PCF)* classification, and feature more than 99% selected secondary raw materials. The PCF is the industry’s first classification for calculating and classifying the carbon footprint of carbide products. The system can be integrated into any product data sheet or sales document, and the roll out across CERATIZIT’s product portfolio is ongoing.

*In line with the ISO 14067:2018 standard, the PCF includes not only emissions attributable to Scopes 1 and 2, but also the upstream part of Scope 3 emissions that can be attributed to specific products (purchased goods and services, upstream transport and distribution, and waste from ongoing operations).

www.ceratizit.com/int/en/sustainability.html