SNEAK PREVIEW: IMTS 2024

IMTS – The International Manufacturing Technology Show will be held at Chicago’s McCormick Place, September 9-14.

Posted: June 14, 2024

The IMTS show is the place where the creators, builders, sellers, and drivers of manufacturing technology come to connect and be inspired. This year’s event will feature more than 1,200 exhibitors that will display their products and productivity solutions across 1.3 million net square feet of show floor. Outlined below is a small sneak preview of what visitors can expect to see at exhibitors’ booths.

Industry’s First Digital Profile Grinder Among Grinding and Sawing Solutions

AMADA Machinery America, Inc. (Brea, CA) is committed to helping customers deliver dependable service and top-quality work with exceptional grinding and sawing solutions. AMADA Machinery will be showcasing saw automation from various bandsaws in Booth N-237200. Make sure to stop by to see the Pulse Cutting Saw in action with a power roller conveyor. Also, on display, will be the HFA360P, Horizontal Post Style Saw, showing a modular material handling system with sorting bins.

Other saws on display will be the CMII75DG, Circular Saw. This is a high production saw which produces fast and straight cuts. The circular saw will feature a new modified loading system for both square and round bar material. The VT5063SW, Vertical Tilt-Frame, will feature a custom mini-handling system with a 2-strand chain-loader and electric work ejector bar. This saw miters up to 60° left and right and will cut bundles.

AMADA Machinery will be introducing the DPG150, Digital Profile Grinder. This is the industry’s first profile grinder with a measurable digital projector. The profile grinder enables high-precision profile grinding with a new digital measurement, which dramatically improves productivity and part processing. Stop by to see how well the projector displays detailed shapes on a 4K monitor. Alongside the DPG150 will be the SSR-6, Rotary Surface Grinder. This grinder provides enhanced usability and exceptional efficiency while the enhanced feed axis speed shortens setup time.

Along with the band saws, AMADA Machinery will also feature a Spartan Ironworker. The Spartan MSIW60D Ironworker has five workstations, with LED lighting, and has the strongest stripper in the industry. AMADA Machinery America keeps your best interest in mind maintaining the philosophy of “Growing with our Customers.”

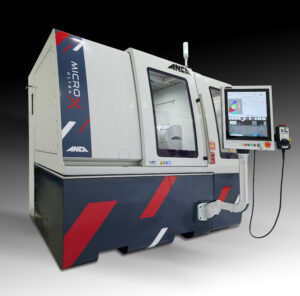

ANCA will Highlight MicroX ULTRA Grinding Machine and AIMS Connect

Eight machines plus the newest ANCA CNC Machines’ (Wixom, MI) ANCA Integrated Manufacturing System (AIMS) will be featured in Booth N-237406. The company is also celebrating its 50th anniversary this year. In addition to the introduction of an advanced, high-precision tool grinder, the MicroX ULTRA, as well as the next generation of integrated manufacturing technology, AIMS Connect, ANCA will further highlight its commitment to offering the best-in-class solutions for tool grinding production, start to finish, which includes the recent opening of its newest tech center in Temecula, Calif., to serve its fast-growing West Coast market base.

As a mainstay in the precision tool industry, ANCA will showcase its commitment to excellence through new products, cutting-edge technologies and exciting business events, including its popular Tool of the Year and Female Machinist of the Year awards. The anniversary showcase addresses manufacturers’ needs for highest quality and lowest cost tools, plus freeing operators from repetitive and non-value-add tasks to make room for progress and creativity.

Pat Boland, ANCA co-founder, remarked, “For 50 years, ANCA has been on a journey to change the shape of the cutting tool industry. To celebrate our 50th anniversary, we look forward to meeting with our customers and partners at IMTS. As innovation has motivated us throughout our history, new products and developments will be at the center of our celebrations.”

Added Edmund Boland, ANCA’s general manager, “Building on ANCA’s heritage of producing industry-leading software, the latest release of our signature ToolRoom software, RN35, takes cycle time optimization even further, elevating productivity – it’s the future of tool production.”

The latest version of RN35, offers:

- Average performance increase of up to 20% with advanced features and functions, optimizing feed rate, improving cycle time and surface finish, while extending wheel life.

- New developments including the integration of material removal rate calculations, allowing manufacturers to automatically set parameters for constant removal rates, plus air-time reduction.

- Statistical Process Control (SPC) software for statistical analysis and evaluation of manufactured part characteristics streamlines manufacturing processes.

- Profile fluting further enhancing the popular flute from solid feature of the proprietary ANCA software.

Experts will present these and other upgrades to IMTS visitors, plus further exciting news in CIM3D simulation software. ANCA invites visitors to Booth N-237406 to experience firsthand all of its innovative machinery and the future of tool manufacturing.

CERATIZIT USA to Unveil Local Innovations and Global Capabilities

CERATIZIT USA (Schaumburg, IL) announced it will showcase high performance tooling for component and industry solutions and emphasize its integral role within the CERATIZIT global carbide supply chain.

As part of a larger organization with a robust presence in Europe, CERATIZIT USA brings unique capabilities to its customers in terms of its vast cutting tool portfolio, technical expertise, and engineering support. CERATIZIT USA’s Booth W-431900 will reflect its commitment to delivering top-tier solutions by highlighting its connection to the broader organization and the extensive resources available through its global network.

“Our attendance at IMTS underscores our dedication to providing our customers in the U.S. and Canada with access to world-class tools and technical support,” said Dan Cope, president of Americas at CERATIZIT. “By leveraging the strengths of our global network, we can offer a comprehensive portfolio of metal-cutting solutions that empower manufacturers to excel in their sustainable business practices.”

At the booth, attendees can expect to see a diverse range of tools from CERATIZIT’s extensive portfolio, including products featured in the company’s highly anticipated new catalog. Scheduled for release on August 1, 2024, the catalog will showcase a selection of metric and inch tools tailored specifically for metal cutting production in the U.S. and Canadian markets.

In addition to the debut of its new catalog, CERATIZIT USA will unveil a new end mill, specifically for titanium and super alloys. Manufactured at its facility in Sacramento, Calif., this new offering exemplifies the company’s commitment to innovation and its ability to develop solutions that address the evolving needs of its customers.

“CERATIZIT’s new end mill represents the development, engineering and testing resources we have access to globally,” said Scott Walrath, business development leader for solid round tools. “Those resources combined with our team’s dedication to push the boundaries of tooling technology is what we deliver to our local customers.”

One section of the CERATIZIT booth will be dedicated to a customer journey and how VAC Motorsports manufactures a billet block engine and other components for BMW racing enthusiasts using CERATIZIT tooling. A BMW race car owned and driven by customer, manufacturer, and race car driver, Tony Salloum, will be on display in the booth.

www.CuttingTools.CERATIZIT.com

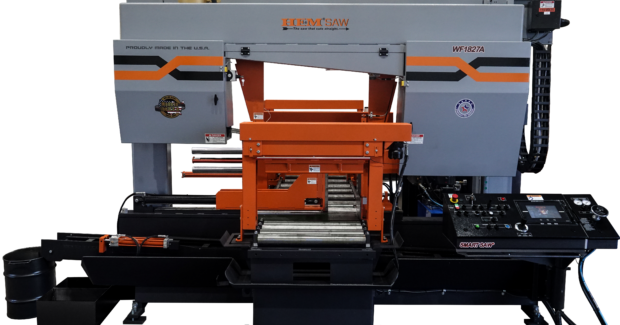

Band Saw from HE&M Saw is a Proven Leader in Performance

The HE&M Saw (Pryor, OK) WF1827A band saw is well known for sawing excellence in cutting bundles and structural shapes. This is largely due to the engineering that went into the design of the saws. Now armed with HE&M Saw’s Smart Saw® control, the capabilities are greatly expanded. HE&M Saw will be in Booth N-237323.

The touch screen control allows the operator to set the saw up to cut manual, semi-automatic or fully automatic jobs. The jobs are easily entered and stored in a Job Library for later recall and use; and each job can contain up to 20 different steps (parts), which enables the operator to cut different lengths out of the same material. The job data includes the material type and sawing parameters such as blade speed, cutting force, arm height, part length, and much more. The Multi Language feature allows for changing the language from English to Spanish, German, or French to help operators not fluent in English; and the operation can be switched from standard to metric units.

The Smart Saw control also has a screen of help files and provides easy access to the saw information displaying items like the machine serial number and blade size. Other help files include a Safety Guide, HE&M Saw’s Practical Cutting Guide, a PM Service Guide, among other information useful to the operator.

One of the newer additions to the saw is that it is Industrial IOT Ready for MT Connect® output, which provides the ability for other machine tool manufacturers to use their own vocabulary to communicate data in a royalty-free standard. It is built to allow equipment and systems to communicate data to be used for monitoring machine output, determine job scheduling, predictive maintenance, and a means to extract real-time data on productivity.

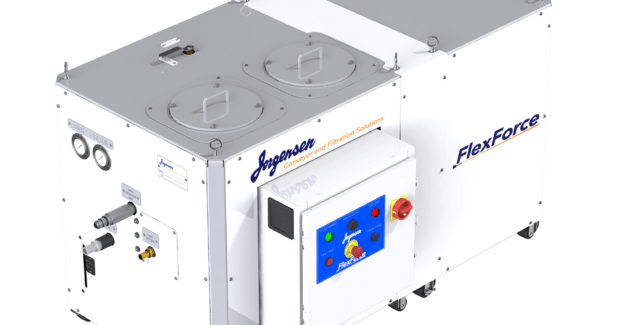

Jorgensen to Feature Conveyor, Filtration and Coolant Solutions

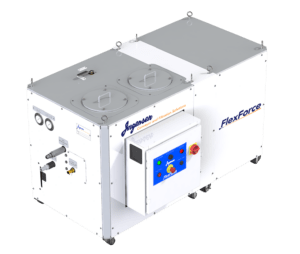

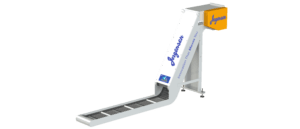

Jorgensen Conveyor and Filtration Solutions (Mequon, WI), now a member of the Innovance family of companies, will feature key products from its comprehensive lineup of conveyor, material handling, coolant and filtration solutions. Visitors to Booth S-338009 will experience a cutting-edge PermaClean system equipped with the new EcoFilter®80 self-cleaning conveyor and a Will-Fill automated coolant system; MunchMan® Dual-Belt Conveyor; FlexForce high-pressure system with a new chiller option; a next generation Magnetic Conveyor for ferrous materials; the ER20T Eco Briquette Press; and the Flex G line that’s part of the company’s FlexFiltration systems.

Jorgensen’s EcoFilter 80 self-cleaning conveyor enables efficient filtration of fine chips to 80-microns nominal. It is the first economical non-drum style conveyor offering filtration below 100 micron. EcoFilter conveyors use non-disposable filter boxes that dramatically reduce chips and particulate from migrating to a machine tool coolant tank. Users experience reduced downtime for tank cleaning and maintenance as well as improved pump, tooling and coolant life.

The EcoFilter 80 will be part of the revolutionary PermaClean system, which adds options for secondary tank filtration and eliminates sludge build up by adding agitation to the coolant collection tank. PermaClean can be incorporated into Jorgensen’s multi-step filtration system and is adaptable as an option to nearly any filtration system on the market.

This system will also be equipped with a Will-Fill total coolant health system that offers trouble-free monitoring of metalworking emulsion. The system combines automatic measuring, filling and conditioning. It alerts operators via a flashing color LED, buzzer, or e-mail when attention is required.

For applications that produce long, stringy or nested balls of chips, Jorgensen’s MunchMan dual-belt conveyor is a heavy-duty unit designed to grab chips as they move into the conveyor’s incline section, greatly reducing or eliminating conveyor jamming problems. MunchMan conveyors are custom fabricated to meet customer requirements and are compatible with other Jorgensen coolant management options.

Booth visitors will also see a new FlexForce high-pressure coolant system for through-spindle coolant system (TSC) applications. Jorgensen will display the 1,000-psi configuration featuring a new chiller option. FlexForce gets coolant directly to the cutting zone, improving lubrication and heat dissipation. The outcome is improved cutting speeds and feeds, chip control and part surface finishes.

Innovance sister companies ALMCO and Mass Finishing, Inc. will be joining Jorgensen at IMTS.

KYZEN to Feature Extensive Line of Metal Cleaning Chemistries

KYZEN Corp. (Nashville, TN), the global leader in innovative environmentally responsible cleaning chemistries, will feature its Clean Team in Booth S-338775, offering cleaning expertise and insights to meet an array of metal cleaning challenges.

KYZEN proudly offers a complete line of products to meet the challenges faced by many manufacturers today. KYZEN provides cleaning solutions to assist in everything ranging from replacing solvents that may soon be hard to get or completely banned to finding a chemistry that cleans and protects metal parts with one solution for the whole process and much more.

Cleaning chemistries from KYZEN are designed to be effective for precision metal and critical cleaning applications including medical devices, automotive, defense and aerospace. Whether the cleaning process and challenges demand aqueous cleaning agents, vacuum degreasing solvent cleaners, or vapor degreasing solvents, KYZEN will work to find the solution that fits your particular cleaning need.

For example, KYZEN provides options to “future-proof” cleaning processes from bans and restrictions with solvent replacements to serve as safe alternatives for traditional solvent cleaning processes affected by recent EPA restrictions and the current phasedown in production of materials containing PFAS and HFCs. They also offer drop-in replacements for 3M Novec solvents that will soon be unavailable.

Regardless of process or the cleaning objective, KYZEN is prepared to provide chemistries to meet the challenge.

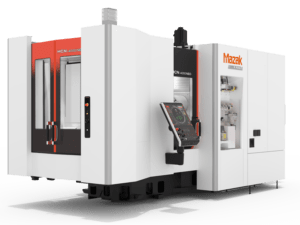

Mazak to Unveil new and Expanded Product Lines

In Booth S-338300, Mazak Corp. (Florence, KY) will showcase its ongoing commitment to continuous innovation in machine tool technology, automation and digital solutions designed to help manufacturers do more and make more. Must-see technology for job shops, multitasking, advanced manufacturing and high-production will be featured in live demonstrations processing real-world industry-specific parts.

Mazak’s booth will feature a wide range of machines from its Ez, SYNCREX, QUICK TURN, NEO and INTEGREX series. Booth visitors will also see Mazak’s most recent automation and digital technology and discover industry-leading Mazak MPower Complete Customer Care, as well as Mazak Capital Equipment Financing for streamlined equipment financing.

Mazak continues to expand its Ez Series of machines with the addition of a 50-taper VC-Ez 32 with its 32” Y axis, and a new 5-axis model — the VC-Ez 20X — which will process parts in the job shop area of the IMTS booth. Like all the Kentucky-built Ez machines, the VC-Ez 32/50 vertical machining center provides shops affordable access to Mazak reliability and is highly configurable with a full range of options to meet a variety of production needs. The machine features the MAZATROL SmoothEz CNC that gives shops both MAZATROL conversational and EIA/ISO G-code programming capabilities.

The advanced manufacturing area will showcase several of Mazak’s next generation NEO Series machines. The new HQR 200MSY NEO Series machine will take center stage at IMTS as the company’s first turning center machine platform in the NEO Series line.

The HQR-200MSY NEO Multi-Tasking turning center features two spindles and three turrets — two upper and one lower — for unequaled part processing opportunities and high-volume throughput in a single setup. The machine’s main spindle can handle 4” bar stock while the second spindle is capable of processing bar diameters up to 76 mm.

Visitors will also see the HCN-4000 NEO horizontal machining center with a PALLETECH system for automated lights-out production. Designed to maximize productivity for virtually any type of part material, the machine’s enhancements improve every aspect of performance from stability and accuracy to power consumption and maintenance.

“Today’s manufacturers continue to struggle with a lack of skilled labor, surging production demands and an ever-changing economy, and they depend on advanced technology to overcome these challenges and maintain their profitability,” said Dan Janka, president of Mazak Corp. “Mazak has always been front and center at IMTS and in the manufacturing world, and our presence there gives shops the opportunity to learn more, do more and make more despite the headwinds the industry is facing.”

Sandvik Coromant to Showcase Holistic Machining and Engineering Solutions

Sandvik Coromant (Mebane, N.C.), a leading global supplier of cutting tools, machining solutions and advanced manufacturing knowledge, will showcase an expanded offering of technology and services in Booth S-338348.

Going beyond cutting tools, Sandvik Coromant will be exhibiting an extensive array of holistic engineering products and services to help shops with data-driven solutions and machining technology.

Booth visitors can expect an immersive experience that brings together the company’s products, expertise and digital machining technology for a wide range of industries, with solutions that drive greater productivity and manufacturing wellness in advanced machining applications.

“Our presence in the Machine Tool Hall underscores our commitment to providing a streamlined and comprehensive experience for attendees as a one-stop destination for all their machining needs,” said Veronica Messersmith, Americas President for Sandvik Coromant. “With all of our offerings under one roof, visitors can easily explore the full breadth of our advanced technologies and services and discover new ways to drive efficiencies and productivity gains across the entire value chain.”

In addition to its team of Yellow Coat experts, senior leadership from Sandvik Coromant will be in attendance, including Michael Eneberg, global vice president of sales and marketing, and Magnus Ekbäck, vice president of strategy and business development, providing attendees with direct access to the company’s strategic vision and decision makers.

“IMTS is a vital platform for us to connect with customers, partners and industry peers,” added Nicholas Falgiatano, vice president of marketing for the Americas. “We’re excited to showcase our comprehensive solutions and engage in productive dialogue to drive innovation and growth within the manufacturing sector.”

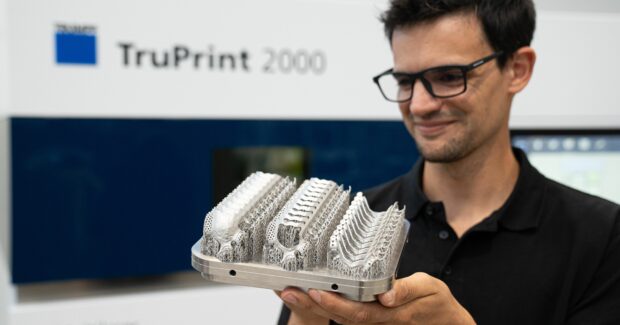

TRUMPF to Showcase Laser and Arc Welding, 3D Laser Marking and AM Capabilities

TRUMPF Inc. (Farmington, CT) will be exhibiting in two booths at the IMTS show: Booth W-433133 and Booth E-135010. In Booth W-433133 in the Additive Manufacturing (AM) pavilion, TRUMPF will highlight the new TruPrint 2000. Introduced in February of 2024, TRUMPF’s TruPrint 2000 now features a larger, square build plate and is designed for more productive, reliable, and high-quality 3D printing. Optimized for serial production, the new TruPrint 2000 offers greater productivity and quality for manufacturers, particularly in the tooling, dental and medical technology industries. The system comes with a 300-watt laser in the basic configuration and is available with increased power from an optional 500-watt integrated fiber laser. The TruPrint is designed for easy and safe powder handling, and the combination of laser power, build volume, and coating time creates an economical machine for series production. TRUMPF’s AM booth features a virtual showroom for participants to take a deep dive into the variety of laser technology and AM applications offered and to help determine the right equipment for different application and part requirements.

In Booth E-135010, TRUMPF will show its automated arc welding, laser welding, and 3D laser marking technology. On display will be the TruArc Weld 1000 automated arc welding system for easy and affordable high-mix, low-volume production; the versatile, compact and fully equipped TruLaser Station 7000 fiber laser welding system; and TruMark Station 7000 with a TruMark 6030 marking laser for high-performance 3D laser marking.