New Perform Solid Carbide Milling Cutters

The tools from Walter USA can be used universally for diverse milling operations with various workpieces, meaning one tool is appropriate for a large range of material types.

Posted: July 18, 2024

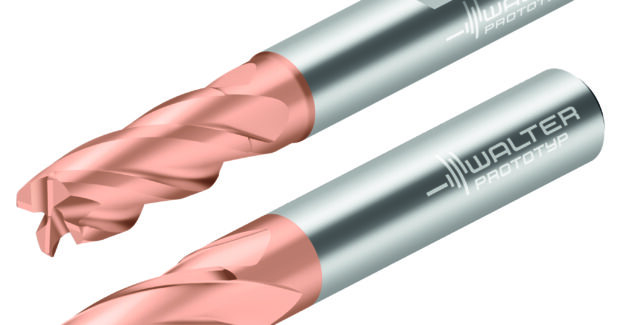

Walter has unveiled the ME232 and ME432 Perform solid carbide milling cutters to add to its range of solid milling cutters. The tools can be used universally for diverse milling operations with various workpieces, meaning one tool is appropriate for a large range of material types. The Perform cutters are designed to be highly economical and are made with the WJ30ED universal milling grade.

The ME232 Perform has a cutting diameter (Dc) from 1/8″ to ¾”, and from 2 to 20 mm, and is available with two, three, four, five or six effective flutes (z2, z3, z4, z5 or z6). The z2 and z3 tools are primarily for slot milling and profile milling, the z4 is for ramping, slot milling and helical milling, the z5 is for roughing and finishing, and z6 is for dynamic milling and finishing. These series offer cutting-edge length (Lc) is from 1 × Dc to 3 × Dc.

The ME232 is suitable for milling steel, stainless steel, cast iron, nonferrous metals and heat-resistant super alloys (ISO P, M, K, N and S material groups). The tools can be used in a range of industries, including mechanical engineering, automotive, energy and tool, mold and die making. The ME232 Perform features the newly developed high-performance cutting (HPC) geometry, with helix pitches tailored to the number of teeth. For example, the z4 cutter has a variable helix geometry with 35° and 38° helix angles.

In the application testing or milling 4140 steel and stainless steel, the ME232 cutter increased the tool life distance 244% and 340%, respectively, versus the competitor.

The ME432 Perform is a ball-nose endmill for roughing and finishing freeform surfaces. The cutting diameter range is from 1/16″ to 5/8″, and from 1 to 20 mm. It is available with two or four effective cutter teeth (z2 or z4) and has a 30° helix angle.

The Walter lineup of products consists of three categories of tools. Supreme tools indicate the highest level of technology and performance available. Advance tools indicate products efficiently balanced between price and performance and Perform tools are products that provide an economical solution with focused importance on price ideal for small batch production.

Walter, a global leader in the metalworking industry for over 100 years, offers a wide range of precision tools for milling, turning, drilling and threading applications. The company helps customers in the aviation and aerospace industries, automotive, energy, and general metalworking industry improve process reliability and increase productivity. As an innovative partner capable of creating digital process solutions for optimal efficiency, Walter is pioneering Industry 4.0 throughout the machining industry. With Regional Headquarters in Greer, SC, Walter markets its competence brands Walter, Walter Titex, Walter Prototyp and Walter Multiply through a network of channel partners and field engineers across the USA, Canada, Mexico and Brazil. www.walter-tools.com/us.

https://www.walter-tools.com/_layouts/15/tibp/embed.aspx?mediaid=96495517