Innovation, Talent and Teamwork Set ANCA Apart in the Cutting Tool Industry

Now in its 50th year, ANCA CNC Machines is celebrating several highpoints in its storied history, while continuing to offer best-in-class solutions for tool grinding production, start to finish.

Posted: August 2, 2024

Based on ANCA’s long history of innovation and of firsts as a global leader in grinding machines and automated manufacturing technologies, it comes as no surprise that its latest innovation, the ANCA Integrated Manufacturing System (AIMS), was recently recognized by the Manufacturing Leadership Council (MLC), a division of the National Association of Manufacturers.

ANCA was named as a finalist in MLC’s 2024 Manufacturing Leadership awards in the Engineering and Production Technology category. Other finalists included The Boeing Co., Lockheed Martin, ESAB Corp. and Peterbilt Motors, among others.

While ANCA wasn’t selected as the overall winner of the category (the winner was announced in June), the company was elated to be selected as a finalist. “To be a finalist is a great honor,” said Patrick Boland, co-founder and managing director of ANCA CNC Machines. Added Russell Riddiford, ANCA’s president for North America: “ANCA is very proud to be in the running for this award from the MLC. We support the digital transformation effort in both our machine building and motion control operations, as we seek to provide our customers the machines and software needed to move their companies in this exciting new direction, within industries of all kinds.”

ANCA is a market leading manufacturer of CNC grinding machines used for manufacturing precision cutting tools and components across a range of industries including cutting tool manufacture, automotive, aerospace, electronics and medical. ANCA is headquartered in Melbourne, Australia, with North American headquarters in Wixom, Mich., and offices located throughout the world, as well as a network of agents. In the U.S., ANCA opened its newest technical center in Temecula, Calif., to serve its fast-growing West Coast market base.

The MLC has recognized ANCA’s AIMS as a leading solution in the tool and cutter grinder industry. AIMS, known for its integrated automation system, combines grinding, metrology, and materials handling to enable 24/7 tool production across various tool applications. Its open ecosystem allows users to connect, automate, and optimize all production steps for cutting tools used in automotive, medical, aerospace, and other sectors. Embodying Industry 4.0 principles, AIMS is rapidly gaining popularity.

ANCA’s new offering, AIMS Connect, is designed for both existing and new customers. It centralizes all manufacturing processes through the AIMS Server, storing all grinding operations with clear instructions on mobile devices. AIMS Connect also facilitates closed-loop measurement and grinding parameter adjustments to ensure precise tolerances. It serves as an accessible entry point for manufacturers aiming to leverage connected and integrated tool manufacturing in the Industry 4.0 era.

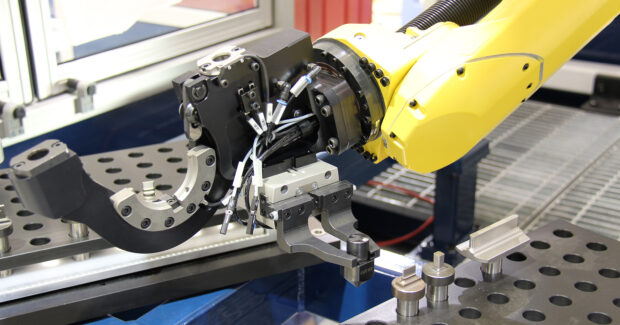

AIMS Automate takes the Industry 4.0 journey further by fully automating the processes connected by AIMS Connect. Autonomous Mobile Robots manage the transfer of pallets, individual tools for measurement, and delivery of wheel packs or collets. The AutoComp software module ensures tools are measured and compensated according to recipes, maintaining batch tolerances during extended unmanned production. The self-optimizing job scheduler maximizes machine utilization across work centers.

AIMS Create simplifies the recipe creation process for tool manufacturing. It enables defining all necessary steps using a single AIMS application, streamlining the production workflow.

ANCA AIMS ensures optimized machine use and high tool quality. Through tool measurement and compensation strategies, scrap is reduced, and cost per tool is significantly lowered. Additionally, reporting and insights supported by Artificial Intelligence provide full visibility into operations. Designed as an open ecosystem, AIMS allows the integration of third-party machines and workstations.

Boland said ANCA is amping up the power efficiency of its machines, in order to minimize the consumption of electricity used in the production cycle. By capturing machine data in real time, operators can optimize inputs such as the temperature of the coolant in order to make reductions in energy consumption. Boland said customers throughout the world continue to request sustainable machines so they can lower their carbon emissions and carbon footprints.

ANCA will demonstrate AIMS Connect, the next generation of integrated manufacturing technology, at the upcoming IMTS show in September at Chicago’s McCormick Place. The manufacturer will be located in Booth N-237406. Also on demonstration will be the latest version of its ToolRoom software RN35, and the newest iterations of its current machine models, including the U.S. introduction of a new product for edge preparation of cutting tools, the EPX-SF stream finishing machine. It features 11-axis automation and smart recipe fine-tuning to provide precise edge control. The EPX-SF reduces edge roughness to under 100 nm and refines edge radii to mere microns with controllable K-factor, achieving nano-smooth surfaces and micron-honed edges in record time.

Fifty Years and Counting

The year 2024 is a monumental year for ANCA, as it marks its 50th anniversary. Boland co-founded the company with Patrick McCluskey; the “two Pats” have expanded their operations from Melbourne to the world. In May, Boland travelled to Wixom to celebrate the milestone anniversary with the North American team. “For 50 years, ANCA has been on a journey to change the shape of the cutting tool industry,” he said. “ANCA’s future is exciting, we are focused on continuing to invent and deliver groundbreaking technology to help take cutting tool production into areas not previously thought possible.”

ANCA started in 1974 with a minicomputer and teletype installed at Boland’s home, followed by a CNC and then the design and manufacture of machine tools. Throughout the years, ANCA has brought significant advantages to the industry with pioneering innovations like the first touch probe, soft axes and 3D simulation. Boland said utilizing probes in the manufacturing process gave ANCA its first edge in the marketplace, expanding from a small company in Melbourne to selling to significant companies across the world. And regarding its 5-axis control system, ANCA’s advanced features made the programming of cutting tools much easier. “So, soft kinematics, redundant axes, advanced part programming language, all made contributions,” Boland added. “It took a number of years before our competitors could copy us.

“We are very proud of our technology and our customer base and our contribution to manufacturing technology,” Boland continued. “There’s been a continuous increase in the requirements and performance of cutting tools and our machines have played their part in the ability to produce these very complex components very reliably at quite a relatively low cost.”

Boland noted that cutting tools have a complex geometry, using difficult material, where the accuracy of the final machine tool is limited by the accuracy of the cutting tools it uses. “So, our technology really underpins a whole suite of industries in manufacturing,” Boland said.

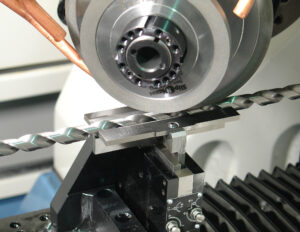

Today, software and automation are key highlights of ANCA’s anniversary tour’s innovation portfolio. (Boland is on a celebratory tour to meet with customers and partners throughout the world.) The latest version of ANCA’s ToolRoom software, RN35, offers an average performance increase of up to 20% with advanced features and functions, optimizing feed rate, improving cycle time and surface finish, while extending wheel life. Among other new features is the integration of material removal rate calculations, which allows users to automatically set parameters for constant removal rates, plus air-time reduction.

In addition to the new features in the RN35 software, ANCA is also highlighting its revolutionary ULTRA technology, which combines nanometer control, servo-controlled algorithms and mechanical stiffness upgrades so manufacturers can achieve accuracy.

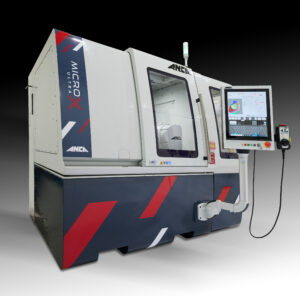

Both the FX7 ULTRA and MicroX ULTRA demonstrate ANCA’s commitment to precision, enabling continuous batch production down to 0.03 mm, setting new standards in tool manufacturing.

The 6-axis MicroX ULTRA provides micro tool manufacturers with all the advantages of the ULTRA technology and ANCA’s Machine Intelligence in a unit tailored to this application. The micro tool grinder features a nanometer control, optimized mechanical layout and axes travel, integrated tool measurement and progressive automation.

“Our ULTRA package is a quantum step in the performance of cutting tool machines,” Boland said. “There are a number of, what I believe, are significant steps through the whole cutting and machining world. So, one is the use of tubular linear motors instead of ball screws. We have a unique in the machine tool world using this technology, and to us, it provides a number of advantages in terms of machine accuracy and reliability.”

Boland added that ANCA is using very advanced algorithms in its servo drives, which enable very high accuracy contouring. “Believe it or not, with our servo drives, we can contour more accurately than the information given in the feedback devices.”

ANCA is also implementing artificial intelligence concepts such as repetitive roll to compensate for errors in the runout in the cutting tool, and in the grinding wheel for system. “We can learn the repetitive disturbance caused by that and compensate in real time,” Boland noted.

The Future: Immense Innovation

In addition to its machines for cutting tools, ANCA also offers machines for non-cutting tool applications. ANCA has partnered with GDS, a German manufacturer of high-quality precision accessories for grinding and machining processes. One of its flagship products is the µGrind workholding, which is available through ANCA’s distribution network. The µGrind has been customized to the requirements of ANCA’s grinding machines and can be set up in a matter of minutes, providing minimal and consistent runout, one of the prerequisites for successful grinding.

And, in the fabrication industry, “there’s a huge number of punches used in chip punching of sheet metal,” Boland said. “The actual grinding of manufacturing of punches — sheet metal is one of our significant markets as well.” ANCA offers the TX7 Linear and TXcell Linear for these production needs and has developed several accessories and options to support punch grinding, including punch programming software; on-machine wheel balancing software; in-process software to keep rotary wheel dresser units sharp; and coolant nozzles that change position as the wheel diameter reduces.

TX7 Linear is a 5-axis grinding machine, compared to the 3-axis grinder traditionally used for punch manufacture, which provides greater freedom with applications. The two-wheel packs on the TX7 Linear enable machine shops to perform several functions related to punches in a single setup. With the TXcell Linear, which offers nine-to-24 wheel packs, multiple operations can be done in a single setup — which is not possible on a standard punch grinding machine. What’s more, the TXcell robot used for changing wheel packs can also be used for the automated loading of tools, enabling unattended operations.

In the future, ANCA’s team will continue to focus on developing machines, software and services that deliver accuracy and reliability, at a favorable price point, and which comprise a smaller footprint.

“Those pressures [sustainability] will continue and there will be incremental advances in all different aspects in software, mechanical design and grinding technology,” Boland added. ANCA will also continue to work with customers to provide solutions to meet their demands and address their pain points. “Customers are looking for higher performance, more accuracy and better surface finish,” Boland said. “We provide that to our customers with our products.”

ANCA’s Annual Awards for Trailblazing Toolmakers and Female Machinists

The highly anticipated ANCA Tool of the Year 2024 winners and the Female Machinist Award will be announced at this year’s IMTS show, which will be held in September in Chicago at McCormick Place. ANCA’s customers submitted tools for consideration from May 15 to July 31 of this year.

Regarding toolmaking innovators, the winner of #MadeonANCA receives a trip to ANCA’s headquarters in Melbourne, Australia; $10,000 AUD worth of ANCA parts, accessories or software; and access to exclusive opportunities with ANCA experts. ANCA customer entrants submit their favorite tool, recognized for both functionality and creativity, and judged on the form and performance of this cutting tool.

The Most Innovative Tool Design segment is for virtual tools; entrants are encouraged to be creative and use ANCA tool design software to push ideas to their limits. The winner receives $10,000 AUD worth of ANCA parts, accessories or software.

“Over 50 years, ANCA has transformed the cutting tool industry with innovative thinking, driving us to continually invent and innovate,” said Patrick Boland, ANCA co-founder and managing director. “As we celebrate this milestone, we are inspired by our customers who share our ethos, creating spectacular designs with our technology.” Partners and sponsors for the competition include Zoller, GDS, Tyrolit and Oelheld.

ANCA’s Female Machinist Award returns for its second year in 2024, recognizing and honoring the outstanding achievements of female machinists in the tool and cutter grinding industry. Women who work with ANCA technology are evaluated based on:

- Exceptional problem-solving skills to overcome challenges or obstacles during projects.

- Innovative and effective tool design.

- Demonstrated ability to think critically and find innovative solutions.

The winner of the Female Machinist Award receives a fully funded ticket to attend a prominent trade show where ANCA is exhibiting; exclusive access to the ANCA team, including the leadership team, engineers, and product experts; and opportunities to connect with industry professionals, gain insights into the latest technologies and attend educational seminars and workshops. “The ANCA Female Machinist Award competition celebrates not only skill but also diversity, highlighting the vital role that women play in shaping the future of manufacturing,” said Meaghan Ziemba of Z-Ink Solutions, and Mavens of Manufacturing, the 2024 judge. “I am honored to have a chance to recognize their excellence and inspire the next generation of female machinists.”