IMTS 2024-Machine Components/Cleaning/Environmental

The latest cleaning and environmental technology will be featured in Chicago at IMTS 2024.

Posted: August 1, 2024

Metalworking Fluid Tackles the Challenges of Titanium Machining

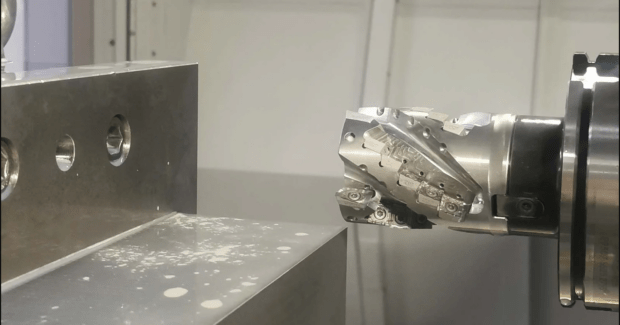

Titanium and high-nickel alloys burn through inserts and cutting tools like no other materials, especially when roughing. As a result, tools are often changed earlier than necessary simply as a precaution. At IMTS 2024, Blaser Swisslube (Goshen, NY) features new metalworking fluids designed to address these challenging applications while lowering overall production costs. Blaser Swisslube will be in Booth W-431228.

The Skytec family of products was developed by a team of experts including chemists, engineers, and application technicians, and tested by well-known machine tool builders and aerospace OEMs. Vasco Skytec H 600 draws on the plant-ester-based Vasco range, and B-Cool Skytec 500 on the mineral-oil-based B-Cool range. Both are designed to significantly extend tool life without risking expensive aerospace parts.

These Skytec products are the ideal metalworking fluids for titanium machining because they minimize tool wear and reduce the number of tool changes without compromising process reliability. They are also suitable when machining aluminum, steel and nickel-based alloys. The fluids perform without foam even in high-pressure systems greater than 1,000 psi.

In real-world tests of Vasco Skytec H 600, tool life immediately increased by more than 40% when roughing titanium. When this initial optimization is followed by an adjustment of the machining parameters in cooperation with Blaser’s application engineers, it is possible to also reduce the machining costs per component. Optimizing both the tool life and machining time per component brings the best possible leverage effect of the metalworking fluid into play.

B-Cool Skytec 500 has additionally been optimized for long term, stable use in coolant reclamation and aluminum chip briquetting systems. The remaining coolant from the chips can be filtered and re-used without the need for tank side additives thus providing additional value and sustainability benefits.

Qualifying tests by independent external laboratories are common before aviation approvals can be obtained. Many of these necessary qualification tests and subsequent approvals have already been successfully achieved by Blaser Swisslube.

Innovative Multi-frequency Ultrasonic Cleaning System

Blackstone-NEY Ultrasonics (Jamestown, NY), a pioneer in ultrasonic cleaning technology, is excited to announce the display of its innovative Multi-Frequency Ultrasonic Cleaning System, located at Booth S-338774.

Designed for versatility and efficiency, the Multi-Frequency Ultrasonic Cleaning System boasts an all stainless-steel construction, ensuring durability and reliability in various industrial environments. This system is specifically tailored for cleaning small parts on an intermittent to semi-production basis, offering exceptional performance and precision.

Unlike traditional cleaning methods, the Multi-Frequency Ultrasonic Cleaning System utilizes advanced technology to deliver superior cleaning results without compromising on quality. Whether used for intricate components or delicate parts, this system is equipped to meet the most demanding cleaning requirements.

Blackstone-NEY Ultrasonics has a long-standing reputation as a leader in ultrasonic generator technology. Since introducing sweeping frequency in 1988, the company has continuously pushed the boundaries of ultrasonic innovation, resulting in a portfolio of patented technologies and cutting-edge solutions.

Visit Booth S-338774 to discover how the Multi-Frequency Ultrasonic Cleaning System from Blackstone-NEY Ultrasonics can revolutionize your cleaning processes. The company is part of the Cleaning Technologies Group, LLC, a world leader in providing innovative cleaning and waste minimization technologies to precision and industrial manufacturing markets.

High-Performance Filtration Solutions for Multiple Industries

Rosedale Products, Inc. (Ann Arbor, MI) is a leading technology developer in the field of liquid filtration systems and waste minimization products for customers around the world. With more than 50 years of experience, Rosedale Products offers an exceptional product line that includes high-performance filtration solutions for multiple industries. Rosedale Products’ technicians help customers find the best, most cost-effective approaches to their filtration needs. The company will be located in Booth E-135992.

Rosedale’s product line sets the industry standard in versatility and reliability and includes bag and cartridge filters, basket strainers, automatic back washing filters, filter cartridges, and many special application products. Together with ongoing consulting, troubleshooting, and support from our team of in-house experts, Rosedale provides comprehensive solutions for every critical industry filtration need. Rosedale manufactures industrial filtration products for virtually any industry where liquid and gas flows are present.

We have a vast product line that suits many needs, as well as the flexibility to customize standard products. Our sales staff has knowledge of many industrial practices, giving customers the confidence that their filter solution is the best available for their specific need. Our most popular products are bag filters, pleated cartridge filters, and basket strainers.