IMTS 2024-Software

Digital transformation will be featured at the software pavillon at IMTS 2024 in Chicago.

Posted: August 1, 2024

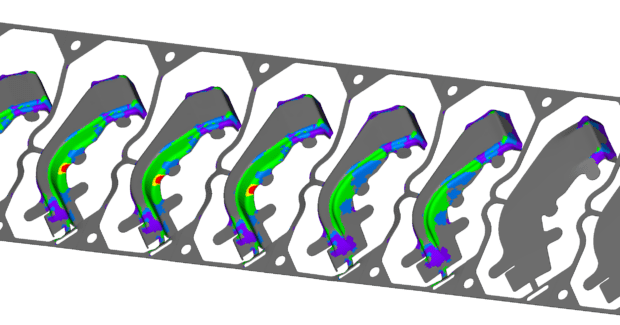

Software for Die Design and Forming Simulation

Accurate Die Design Software, Inc. (Brookfield, WI) are experts who provide software for die design and forming simulation for the manufacturing industry. We will be demonstrating the benefits and capabilities of LogoPress and Stampack in Booth E-135800.

LogoPress has been developing die design software for the tool and die industry as well as flattening and blank prediction software for many kinds of parts since 1989. One of our newest products is ProgSim which is an affordable, easy-to-use, and highly accurate virtual tryout press that runs inside of SOLIDWORKS and LogoPress software as an add-on.

ProgSim quickly performs accurate simulations of forming processes using incremental simulation technology powered by industry-proven AutoForm solver technology. ProgSim allows the user to determine formability and springback at the strip layout stage of a die design. Some of the results provided include thinning, wrinkling, splitting, springback, stress, strain, etc.

Stampack is next-generation, user-friendly, affordable forming simulation software, with a clear and straightforward interface. Stampack includes both shell and solid solvers making it extremely fast and very accurate. The extreme accuracy of the results in Trim Optimization (automatic blank development), Springback Compensation, and Tolerance Check are all due to the solid simulation analyzing all the elements throughout the material thickness.

Stampack accurately simulates everything from large automotive line dies, transfer dies, and progressive dies, to small progressive dies making tiny electrical and medical parts. The solid solver is capable of simulating coining, ironing, deep drawing, and other cold-forming operations that competing software cannot recognize.

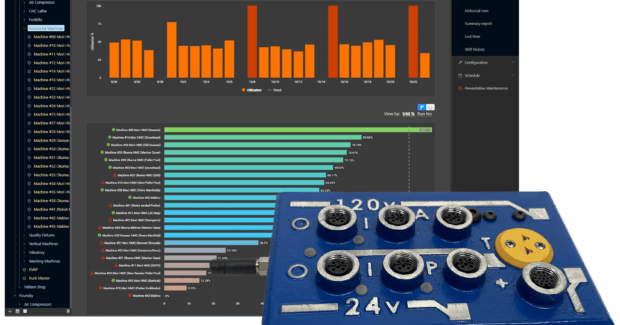

Easy to Install Machine Monitoring Solutions

CADDIS Systems (Bettendorf, IA) will bring its machine and process monitoring solutions to Booth E-135947. CADDIS uses a durable shop floor device and intuitive dashboard for real-time monitoring, providing operators and managers with multiple opportunities for increased Overall Equipment Efficiency (OEE), reduced downtime and planned maintenance intervals. Company representatives will give live demonstrations every day of the show, highlighting the system’s capabilities across numerous industries and applications.

“The CADDIS solution is easy to install and offers measurable ROI with quick payback,” said Chris Moore, CADDIS Systems’ vice president. “With different ways to connect to machine and equipment networks, users can choose the setup that works best for them, knowing they’ll get a constant stream of live data and be alerted of any deviance in performance.”

The device is proof tested for many thousands of cycles and made from a sealed aluminum casting to withstand elevated temperatures and remain fully functional in every type of equipment environment including those that may contain salt, gasses, dust, sand, and other elements. Modular add-ons are available and allow users to customize the device with features like a thermocouple expansion, accelerometer expansion for vibration monitoring/analysis, and infrared temperature expansion for non-contact temperature monitoring.

The user-friendly software compiles streaming data into a single integrated system that monitors any machine regardless of brand or type, offering a common set of metrics that are user defined. The system is easily expanded and scalable to keep pace with growing production capabilities and facilities.

New and Flexible CNC Automation Solutions

CNC automation supplier Fastems LLC (West Chester, OH) will showcase its flexible automation systems with experts available to discuss how even the smallest machining shops can succeed in creating automated manufacturing operations in Booth S-338966. Each day will feature educational sessions on machine shop productivity and live Fastems CNC automation system demonstrations as well as live daily customer case studies.

The company will highlight its entire flexible manufacturing system portfolio via Living Factory, and the entry-level automation system Flexible Pallet Tower (FPT), controlled with the industry-leading automation software, MMS (Manufacturing Management Software). FPT automates 4- and 5-axis machining centers with 300-to-630 mm pallets or zero-point plates. As a factory-tested automation unit, it is ready for fast delivery and installation with ready-made interfaces for hundreds of different machine tool models.

The automation control software MMS is designed to plan, run, and control mixed manufacturing, and its latest version 8.2 brings new features related to machining sustainability and flexibility in turning machine tool automation. The digital service portal myFastems enables manufacturers to take the most out of their automation systems every day. Fastems is also displaying its factory MES solution Work Cell Operations that can plan the operation of manual work cells, stand-alone machine tools, and automation systems in a single instance. Factory Cockpit collects, visualizes, and analyzes production data at factory-level for full production transparency and data-based development.

To help manufacturers improve the cutting tool processes that are often the reason for low CNC spindle utilization, Fastems experts will discuss the best cutting tool practices and how automation can help in physical tool delivery and managing tool data, including tool wear. The company’s Gantry Tool Storage and Central Tool Storage tool automation systems help shops to remove machine stops related to tool shortages, minimize their tool reworking time, and reduce sister tooling costs.

Fastems experts, including Mikko Nyman (CEO), Mikko Mononen (CSMO), Heikki Hallila (VP Digital Manufacturing) and Risto Niemi (Head of Expert Sales) will be available for discussion and demonstrations throughout the week during the show.

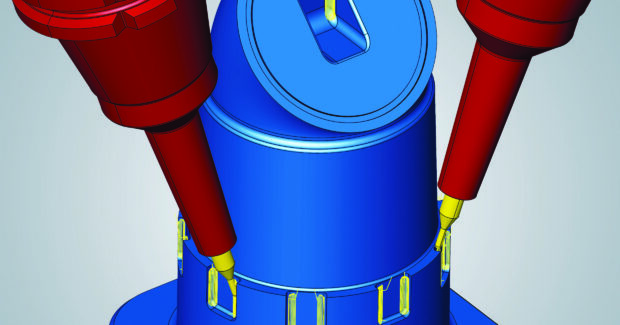

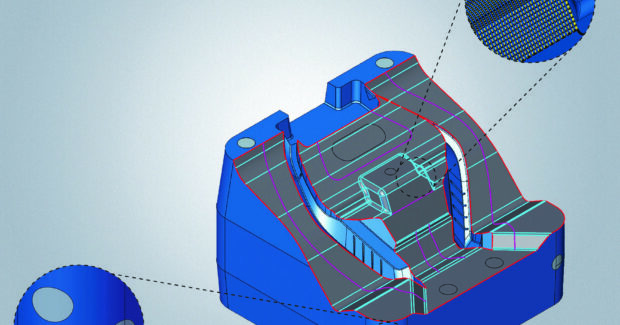

OPEN MIND to Highlight hyperMILL 2024 CAD/CAM Software Suite

OPEN MIND Technologies (Needham, MA), a leading developer of CAD/CAM software solutions worldwide, announced it will be highlighting its new hyperMILL® 2024 CAD/CAM Software Suite at Booth E-133351. The new software suite includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling.

An Optimized Deep Hole Drilling CAM strategy offers improved machining reliability by providing a user-friendly interface with process-relevant parameters clearly defined on a new process tab. New capabilities enable coolant and dwell time stages to be identified, allow a chip break to be integrated into a drilling process, and more. A new single-tip gun drill tool simulation function provides precise collision checking and a detailed visualization of the stock removal.

A new algorithm for 3-axis and 5-axis Rest Machining ensures automatic, complete detection of all rest material areas, in addition to optimized toolpath calculations for faster, reliable machining. Toolpaths are now optimally divided to ensure more efficient machining, and the detection of intersection areas where paths meet has been optimized for collision avoidance.

An additional toolpath improvement is an enhanced path layout for the 3D Plane Machining cycle. The new strategy has a smoother path and fewer pick-ups. While the toolpath length (distance) may be longer in some cases, the machining time, as tested on a variety of NC controllers, has been reduced.

A new, novel generation of programming assistance and analysis, “CAM Plan” is introduced in hyperMILL 2024, simplifying various programming tasks and identifying possible sources of error. Predefined workflow steps safely guide users through the preparation and programming process, while the geometries and features required are automatically created. Also, potential errors are flagged for removal such as double surfaces or gaps between model patches.

For easy generation of 3-axis and 5-axis NC programs with axis change and an optimized use of the workspace, the NC Optimizer feature in the hyperMILL VIRTUAL Machining strategy now offers the option to transform X- and Y-axis movements into a movement that utilizes the rotation axis in the table. By swapping axes, an XY movement is transformed into a simultaneous CX movement which eliminates rewind movements during machining. This is especially impactful on machines that have a limited linear axis range.

The reading back of measuring points when using hyperMILL VIRTUAL Machining is a new feature that allows graphical representation of measured points on the part model, rather than comparing a list of measurement results.

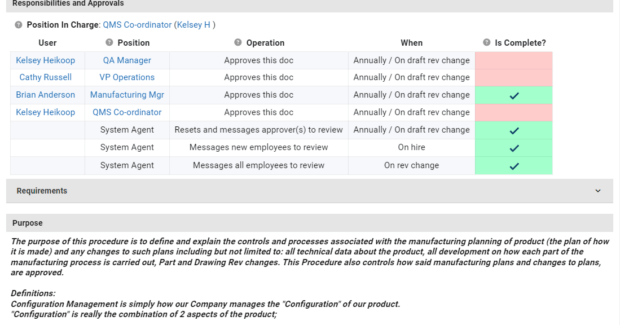

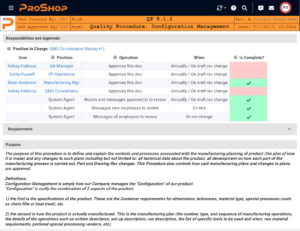

ProShop ERP to Showcase QAP and SAFE Add-Ons to ERP Digital Ecosystem

ProShop ERP (Bellingham, WA) will exhibit the QMS Assurance Plan (QAP) and SAFE™ add-ons to its proven ProShop ERP digital ecosystem in Booth E-133027. The company will also be featuring its Customer Ambassador program where happy customers demo and discuss the ProShop software for interested booth visitors.

The ProShop QAP is an add-on subscription plan which ensures customers that their QMS is constantly updated with the latest standards. This is made possible by implementing the company’s Flying Start package directly into the ProShop QMS-related modules in the digital ecosystem, including those used to manage and certify companies to any quality standard including ISO 9001, AS9100, ISO 13485, API and more. Each QMS template contains the same modules, but they are delivered empty for manual loading or built with custom content when the Flying Start package is purchased. In addition to saving significant time during the certification and recertification process, QAP and Flying Start help to reduce the costs of certification maintenance and enable remote auditing. Optimized for individual operations, QAP helps to streamline the recertification process well into the future. The package also includes ongoing training and support.

The ProShop SAFE (Secure Access File Ecosystem) add on is a secure, innovative cloud-based ERP file management system that enables companies to achieve multi-dimensional, roll/user based data security compliance to multiple standards such as NIST 800-171, CMMC, ITAR, HIPAA, SOC, GDPR and ISO-2700X. ProShop SAFE ensures that only authorized users have access to specific files and folders managed through the unified credentials and authentication of their ProShop login. Combined with ProShop’s GovCloud hosting suite of features, ProShop SAFE dramatically limits a shop’s Controlled Unclassified Information (CUI) footprint and thereby simplifies and economizes compliance efforts, as well as protecting other sensitive company and customer data.

“Certification processes are arduous tasks and can take years to fully accomplish due to the sheer amount of data and documentation required,” said Paul Van Metre, president, ProShop ERP. “The ProShop QAP add-on shaves significant time off the process by consistently updating standards and certification requirements as they occur and, when paired with our Flying Start offering, contains all of the customer’s data from the start eliminating the need to manually upload information into the system. Many certifications require strict data security standards. Application of ProShop SAFE accelerates and simplifies fulfillment of a wide range of security requirements, avoiding possible loss of work while saving money and time.”

Siemens to demonstrate the path to “Empowering The Digital Machine Shop”

Siemens (Chicago, IL) will present its extensive machine tool CNC portfolio and digitalization software technology in Booth E-133249, highlighted by the digital native SINUMERIK ONE control platform for machining applications. Also, using a sports theme of “Speed, Agility and Endurance,” aimed at the machine shop on its path to digitalization, Siemens will introduce MACHINUM to the North American market. MACHINUM brings together machine tool controls, digitalization software and machine shop services from Siemens to help manufacturers optimize their production processes, to provide agility for quick adaptation to changing customer requirements and calculated uptime needs, plus enable digitally proven endurance to maximize the productivity of the entire machine shop or production department.

Detailing the elements of MACHINUM:

- Speed: Siemens adaptive feedrate control reduces cycle times, while maintaining a stable machining process. This results from instantaneous and continuous analysis of the current cutting conditions on a machine tool in real time, automatically optimizing the feedrate.

- Agility: Through strategic digitalization and software that seamlessly integrates the machine tool CNC systems and a shop’s internal communications, MACHINUM can significantly boost the agility of a machine shop or production department to accommodate changes in design, quantity output and even machining characteristics, based upon customer input and overall production and workflow landscape characteristics.

- Endurance: Continuing the sports theme, over the long “run”, MACHINUM enables a heightened level of maintenance capability with leading “edge” machine monitoring that anticipates potential issues before they escalate. This results in reduced costs and substantially less downtime on machines, due to unplanned maintenance. This feature is especially useful for linked and sequential production lines.

MACHINUM also offers substantial benefits to machine builders, as Siemens integrated digital twin technology allows more streamlined off-machine programming and machining simulation in an office environment. This approach facilitates faster prep time, more accurate design specs on the final machine, faster component acquisition near the build time and a reduction in costly downtime, due to last-minute design changes, as those are anticipated, simulated and resolved, all in a virtual world. MACHINUM also represents the integration of existing Siemens digitalization software such as Create MyVirtual Machine, Run MyVirtual Machine, Adaptive Control and Monitoring, Analyze MyWorkpiece and Manage MyMachines.

Under the theme “Empowering the Digital Machine Shop,” Siemens will display its digital threads, from blueprint to finished part, digital twin to simulation, part production, as well as the total integration of these processes into the digital factory for job shops and production departments, all brought to life by Siemens hardware automation and digitalization software.

Visit https://usa.siemens.com/imts for complete booth details.