Using Perforated Metals to Manage Acoustics

IPA explains how perforated materials can be used in acoustical Sound Transparency and Tuned Resonant Absorption.

Posted: April 4, 2016

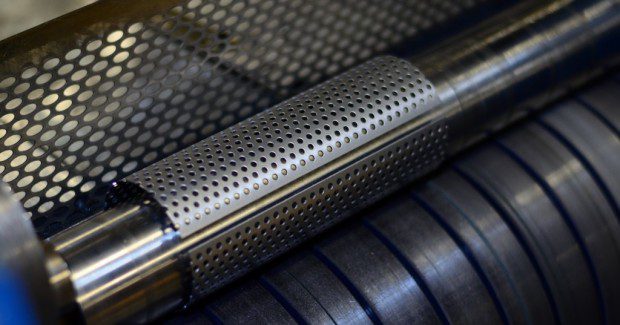

In the acoustical context, there are many materials that are suitable for perforation. These materials, including aluminum, stainless steel, Inconel and titanium alloys, retain excellent strength with perforation. Multiple materials provide many options for hole shape, pattern and size.

The Industrial Perforators Association (IPA; Milwaukee, WI) has a mission to increase markets for these perforated materials. These perforated designs are particularly used for sound abatement and are the most effective and efficient solution for acoustical management. “There are endless opportunities for perforated designs,” said Keith Zinn, the president of IPA. “It has been an easy transition for us to highlight the possibilities of design, to ultimately serve the function of managing acoustics with different applications in any environment.”

Perforated materials can be used in two different acoustical applications, including Sound Transparency and Tuned Resonant Absorption. In Sound Transparency, the perforated metal is used as a protective or decorative covering for a particular acoustical material to absorb, reflect or scatter sound. As a Tuned Resonant Absorber, the perforated metal takes an active part in determining which waves of sound are absorbed. A large part of creating a more pleasant environment involves absorbing or reducing sound. With various designs and applications, perforated materials are the best solution for managing acoustics.

As the only North American organization devoted to the advancement of perforated materials, the IPA continues to push the boundaries of what these materials can do. Through extensive research, knowledge sharing, standards setting and more, the organization provides members with the tools to drive innovation and increase utilization in perforation. In the process, acting as an essential resource to anyone who may benefit from incorporating perforated materials into their design.