Abrasives, Belts, Brushes, Grinding Wheels

Filter by Process Zone:

Tips for Preventing Long Wire Breakage When Using Power Brushes

Typically caused by improper brush use or using the wrong brush for the application, long wire breakage does not fall under normal brush wear. It can be a costly problem that also poses safety hazards for operators and other workers in the area. Here are some ways to help prevent this issue so that you can get longer life and optimal performance from your power brushes.

Jason Industries Names New President and CEO

Brian K. Kobylinski succeeds Jeffry N. Quinn, who remains chairman of their board.

New Brushes, Abrasives, Discs for Surface Conditioning

Advanced abrasives, power brushes, and maintenance products from Weiler address the most demanding grinding and cutting needs.

Cut-Off Disc Cuts Faster, Cooler Through Steel and Stainless Steel

The reinforced rib on the redesigned Zip Wheel cut-off disc from Walter Surface Technologies is more rigid for consistently straighter cuts and more durability to withstand even the toughest materials.

Tips for Choosing the Right Product for Welding and Fabrication Surface Finishing

Here are some insights on how to address the varying levels of surface finishing requirements that depend on industry demands and the eventual end use of the finished product.

PFERD Appoints Technical Sales Specialist

Tim Lee is responsible for working with customers on their cutting requirements, particularly large diameter cutoff wheels.

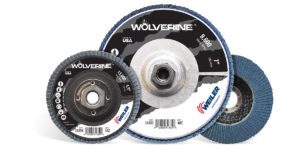

Re-Engineered Abrasive Flap Discs Offer Maximum Cut Rates and Extended Life

Vortec Pro abrasive flap discs from Weiler have been re-engineered under the Wolverine family of discs to deliver exceptional value.

FABTECH 2016 Sneak Preview: Welding

The 2016 edition of FABTECH is on track to be one of the largest metal fabrication events ever at the Las Vegas Convention Center in Las Vegas from November 16-18. This special sneak peek provides technical reviews of some of the equipment, power sources, positioners, systems and accessories that will be exhibited in the Welding Pavilion to help you get a head start on navigating the show floor and managing your time while you’re there.

PFERD Hosts Career Fair

Students and visitors tour their manufacturing facility and learn about various career opportunities within manufacturing.

Metal Finishing Solutions

Files, burs, brushes, grinding and cutting wheels and power tools from PFERD increase operator efficiency, health and safety, and optimize process effectiveness.

Depressed Center Grinding Wheels Remove More Metal Faster with Less Operator Fatigue

For substantially faster grinding, Norton Quantum3 wheels from Saint-Gobain Abrasives remove almost twice the amount of carbon steel at five minute intervals compared to other competitive wheels.

Medical Machining: Tooling

Take a closer look at some of the newest tooling that can help contract manufacturers meet the machining, micro machining, and laser processing demands for smaller and more complex surgical implants, orthotic devices and medical instruments that are being made from newer materials – and still hold their costs down.