Additive Manufacturing Systems

Filter by Process Zone:

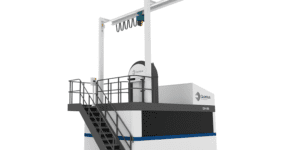

Ascent Aerospace Invests in AM

Their LSAM machine from Thermwood will help them commercialize production-ready additive solutions for aerospace tooling.

Changing Distributorship at GF Machining Solutions

They are expanding channels and regional sales throughout North America.

Sandvik Acquires Stake in Beam IT

This deal strengthens their existing capabilities in metal 3D printing.

Reimagined Parts: Additive Manufacturing Takes Center Stage (Part One)

Additive manufacturing is moving beyond prototypes, part repair and producing non-critical parts, and entering the direct production of critical parts and lot sizes. To deliver these jobs quicker, digital networks are integrating AM with product design software, CAD/CAM, ERP and automation to develop new approaches that can build innovative products faster than ever.

Reimagined Parts: Additive Manufacturing Takes Center Stage (Part Two)

Additive manufacturing is moving beyond prototypes, part repair and producing non-critical parts, and entering the direct production of critical parts and lot sizes. To deliver these jobs quicker, digital networks are integrating AM with product design software, CAD/CAM, ERP and automation to develop new approaches that can build innovative products faster than ever.

True Disruption: 3D Printing Micro Components

Until this micro-AM technology was introduced, the requirements for ultra-precision, repeatable resolution and surface finish from the micro-manufacturing sector were impossible to achieve through the use of 3D printing.

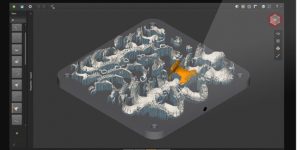

Build Preparation is No Longer an Afterthought

Flow software from Velo3D integrates print preparation, simulation and composing capabilities to predict and control the outcome of building any design and assure its accuracy and consistency.

The New Age of Mold Making

Used in making plastic components for optical applications, this 3D printed mold from toolcraft has optimized topology, is smaller and weighs less, is easier to manufacture and significantly improves the process of producing the plastic parts.

Bigger Prints with Selective Laser Sintering

The next-generation Lisa 3D printer from Sinterit uses PA11 Onyx material to build functional final moving parts, enclosures, latch systems, handles, sporting goods, hinges and fall-proof elements with improved flexibility and outstanding thermal, chemical and impact resistance.

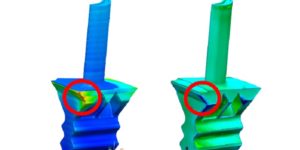

Constructing a ‘First Time Right’ Print

Using a digital twin to simulate the build process prior to printing, Additive Manufacturing Process Simulation from Siemens predicts distortion during 3D printing and automatically generates the corrected geometry to compensate for it.

Software to Automate Build Preparation, Monitor the Build Process

Renishaw offers QuantAM Dental to cut build preparation time for hundreds of dental frameworks in a single operation, and InfiniAM Spectral to analyze process monitoring data in real-time.

Advanced Post Processing for Leaner Additive Manufacturing

By combining heat treatment and cooling into a single process for stress relief, heat treating and aging of parts in a single cycle, the QIH 60 hot isostatic press from Quintus reduces the number of steps in the production line to accelerate the AM process.