Additive Manufacturing Systems

Filter by Process Zone:

Another Way to Build Complex Parts with Dissimilar Metals

Laminated object manufacturing uses diffusion bonding to fuse thin layers of similar or dissimilar metals together and build complex metal parts with internal passageways for conformal cooling, heat exchangers, liquid/gas dispensing and other difficult applications.

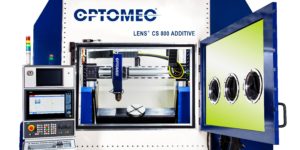

Next Generation Controlled Atmosphere DED Systems

LENS CS 600 and CS 800 Controlled Atmosphere (CA) DED systems from Optomec provide high cost-to-performance ratios on demanding jobs ranging from precision deposition to cladding applications.

Hybrid Systems Finish 3D Printed Parts in Single Setups

Hybrid multi-tasking technologies from Mazak combine both additive and conventional subtractive processes to eliminate work-in-process, reduce lead times, improve part accuracy, shorten setup times and streamline processes.

Game Changer: 3D Printing H13 Tool Steel

For manufacturers of high volume plastic parts and those building injection molds or tooling for high strength, high temperature applications, this hot-work tool steel from Markforged can now be printed with unique and complex geometries to accelerate their speed to market.

Why the Cheapest Powder Doesn’t Produce the Cheapest Parts

Additive manufacturing may be at the cutting edge of production technology, but LPW Technology proves how the old rule still applies when it comes to the quality of material: buy cheap, buy twice.

Sawing 3D Printed Parts

Using an integrated 180 deg turning device and intelligent control system, the automatic KASTOwin amc band saw from KASTO makes individual precision offcuts of 3D printed components with maximum productivity and safety.

3D Printed High-Strength Aluminum

HRL Laboratories commercialized their 3D printed high-strength aluminum and obtained the first-ever registration of an additive alloy from the Aluminum Association.

3D Printing at a High Price/Performance Ratio

The economical Pro 3 additive platform from FELIXPrinters provides dual extrusion functionality, the ability to switch to a stainless steel nozzle for carbon reinforced printing, a larger build plate size and extreme layer resolution with low failure rates.

The Power of Additive Machining

The Additive Machining module in Edgecam 2019 R1 software from Vero accurately guides a laser as it deposits material to build a shape using direct energy deposition, then uses advanced rotary and five-axis milling cycles to finish the final shape.

Flexible 3D Printing of Components with Finished Part Quality

Using selective laser melting driven by self-adjusting and learning algorithms to create very small, highly complex parts from different materials, the Lasertec 30 SLM five-axis powder bed fusion machine from DMG MORI has an intelligent powder module that can change materials in under two hours.

Printing Parts for Extreme Temperature, Highly Corrosive, Marine-Grade Environments

Printing 316L stainless steel with the Studio System from Desktop Metal is another step to fundamentally changing the way metal parts are designed and manufactured for the most demanding applications.

Shaping the Future of Manufacturing

3D printing capabilities in various additive systems from Cincinnati Incorporated range from quickly creating prototypes to unattended production of complex parts, with part simulation in all stages of fabrication that dramatically reduces waste in part design and accelerates advancement to production.