Additive Manufacturing Systems

Filter by Process Zone:

TRUMPF Expands Training Center

With this 18,000 sq ft expansion, they are now capable of training 5,000 students within 630 training events a year.

Cincinnati Incorporated Expands Sales Engineering

Eric Blasiman has been appointed as a sales engineer for the Midwest, including Northwest OH and Southeast MI.

Cincinnati Incorporated Names New Sales Engineer

Nick Thielmann is now in charge of sales for the Midwest U.S.

Met-L-Flo Partners with Roboze

They will collaborate on offering innovative AM applications for the defense industry.

Methods Machine Tools Celebrates Milestone

This is their 60th year in the machine tool business.

Additive Industries Signs New Agent in Spain

Análisis y Simulación will help expand their metal 3D printing base, specifically in aerospace and automotive applications.

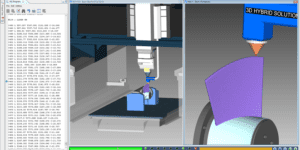

Advancing Additive in Aviation

By integrating VERICUT software from CGTech with metal printing technology on a CNC machine tool, 3D-Hybrid Solutions can apply powdered metal or wire feedstock at rates up to 20 lb per hour, then machine the part to precise dimensions on the same machine with no need for secondary fixtures.

Gas Technologies and Powder Storage Advance the Quality of 3D Printed Aerospace Metal Parts

Ideal for powder-bed laser fusion processes, the portable ADDvance O2 precision atmosphere monitoring system and powder cabinet from Linde precisely controls O2, temperature and humidity levels in the powder process chamber and storage atmosphere.

Ultrasonic Cleaning of 3D Printed Aerospace Parts

The compact 20 gal plug-and-play Omegasonics 1900BTX ultrasonic cleaning machine from Plural Additive Manufacturing uses a specially formulated blend of aerospace quality polyphenylene sulfide to clean parts 3D printed on fused filament fabrication machines from 3ntr.

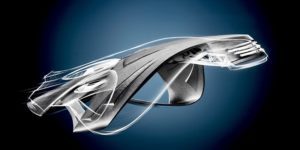

How to Prove-Out Large Aerospace Part Form and Functionality Before Building

Powered by NVBOTS, the SAAM system from Cincinnati Incorporated uses fused filament fabrication technology to 3D print plastic parts directly from a CAD design so that designers can prove-out part form and functionality while saving material and time prior to building out full-scale parts on a BAAM.

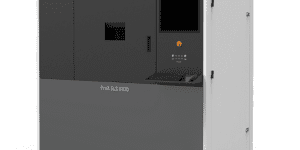

Affordable 3D Printing of Aerospace Interior Cabin Parts

The ProX SLS 6100 laser sintering 3D printer from 3D Systems incorporates production-grade materials, 3D Sprint software and 3D Connect capability for cloud-based monitoring services to seamlessly scale from functional prototyping to low volume functional production for aerospace interior cabin parts.

Fast, Cost Efficient Production of Near-Net-Shape Metal Aerospace Parts

Modular 3-axis and 5-axis GTarc machines from GEFERTEC use 3DMP additive manufacturing technology to build each part welding layer-by-welding layer for maximum material utilization that leads to substantial cost savings of up to 60 percent on expensive materials like titanium.