Automation/Robotics

Filter by Process Zone:

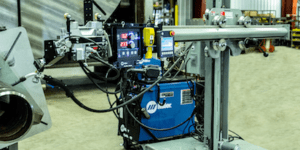

Space-Saving Automated Welding Package for Pipe Fabricators

Koike Aronson Ransome’s pipe-welding package incorporates the Cricket-I manipulator. Providing 20-IPM lift speed and 150-pound load capacity, the manipulator ensures productivity increases without sacrificing floor space.

6-Axis Welding Cobots Provide Maximum Flexibility

Fanuc adds 15- and 33-pound-payload welding cobots to the ARC Mate product line. The arc welding cobots’ easy-to-program interface supports both simple and complex applications using advanced features.

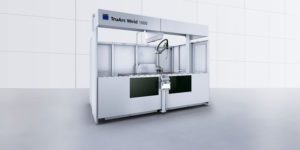

Pre-Engineered Cell Eases Transition to Automated Welding

ESAB and Yaskawa have partnered to offer small-to-medium-sized manufacturers and fabricators a pre-engineered welding cell that’s easy to set up and operate: the XCellerator.

Bystronic Enters Automated Welding Market

Bystronic is selling three robotic welding options – Micro Cell, Compact Cell and Compact System – in the U.S. They’re configured by the German manufacturer Cloos Robotic Welding, which handles installation, training, and service.

Two-Arm Cobot Doubles Efficiency Without Sacrificing Safety

Even though they have two arms, Kawasaki Robotics’ duAro cobots fit into a single-person space while providing enough room for an employee to safely work alongside. Two models provide 8.8- and 13-pound payloads.

Three Updated Cobot Models Offer Greater Connectivity

The “A” in Hanwha’s HCR-3A, HCR-5A, and HCR-12A stands for “advanced.” Three cobot models improve on their predecessors by offering customizable solution packages that incorporate artificial intelligence and mobility technologies.

Design the Ideal Floor Layout for Cobotic Production and/or Assembly

Delmia Robotics’ software from Dassault Systemes maximizes automation initiatives by enabling manufacturers to design and virtually test a drilling-and-riveting, arc welding, spot welding, and/or material handling line before rolling it out.

When (and How) to Automate Sheet Metal Welding

Cobotic welding systems occupy the gap between fast and heavy industrial robots and manual welding. They also challenge the paradigm that welding automation is strictly a high-volume game.

Maximize Your Investment in a Welding Cobot

A collaborative robot (cobot) welds more efficiently, more consistently, and has a longer reach than its human counterparts. Here’s what to consider as you shop for a model that will boost your operation’s throughput and quality.

Flexible Robotic Welding System Reduces Nonvalue-Added Labor by 60%

U.S.-based ACS Industries had a lock on the market for standard attachments – buckets, forks, blades, etc. – for construction equipment, but needed to cost-effectively fabricate specialized implements for related markets. Six-axis robotic welding clinched $1.5 million in new business while lowering labor costs 60%.

ESPRIT CAM and Alma CAM Create Robot Additive DED Programming

The partnership has resulted in a validated workflow that provides end users with dedicated additive toolpath planning and programming, as well as robot programming, simulation, verification, collision detection, and code generation. Engineers can also use the technology to achieve the above functions for subtractive finishing.

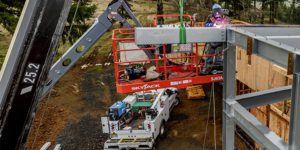

Three Ways to Cut Field Welding Costs

Walking back and forth to a vehicle to tweak an engine-driven welder/generator’s control panel takes time. Remote control devices increase productivity by putting the ability to make changes in the palm of the operator’s hand.