Automation/Robotics

Filter by Process Zone:

Lincoln Electric Acquires Vizient

This deal helps diversify their end market exposure and broadens their growth opportunities in automation.

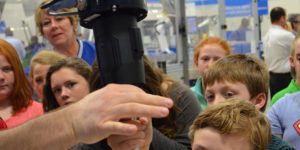

Yaskawa Motoman Demonstrates Career Opportunities to Students

In recognition of National Robotics Week, students toured their facility to learn about industrial robotics and many related career path opportunities.

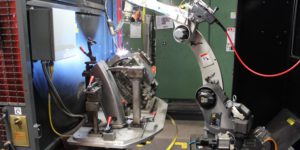

Automating Welding Operations

Increased speed. Higher quality welds. Reduced errors. These are only a few of the many reasons why more shops want to automate work throughout the welding process. Here are some of the latest systems they should consider.

Extended Robotic Welding Range, Speed, Accuracy

ABB Robotics introduces the flexible, compact and modular IRBT 2005 medium track motion platform for automated robotic welding, and the IRB 2600ID integrated dress pack robot with an extended reach and heavy payload that is ideal for arc welding.

Pemamek Expands and Names New CEO

As their new chief executive officer, Jaakko Heikonen leads their business growth strategy.

Workcell for Job Shops

The ArcWorld C-30 system from Yaskawa Motoman includes a six-axis MA1440 arc welding robot, DX200 controller with menu-driven arc welding application software, and integrated welding package.

Ceramic Centring Pins for Automated Welding

Cerazur ceramic welding centring pins from Doceram are extremely durable, with high impact strength that is ideal for the very short cycle times of automated production lines, such car body assembly, where even hardened metal centring pins quickly become deformed and worn.

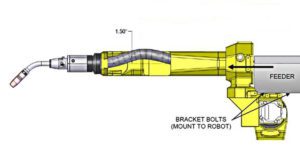

Top Ten Things to Consider with Through-Arm Robotic MIG Guns

Through-arm robotic MIG guns don’t require a mounting arm like conventional robotic MIG guns do. They provide a smaller work envelope that is ideal for working in tight spaces. Here are the top factors in selecting, installing and maintaining a through-arm robotic MIG gun.

A Week in the Life of An Online Data Management System

We can now measure, store and analyze up to 7.5 million weld sessions per day. By automating functions that were once done manually, a shop can save countless hours and provide real transparency into their drivers of productivity, quality and cost control.

Improving Automation with Welding Information

By providing archived data that can be used to lower costs, a welding information management system helps improve the productivity and quality gains offered by automation. This technology helps shops make the most out of their investment in welding automation, increase their competitiveness in the marketplace, and improve their profitability.

Robotics Education Strategy for the Economy

Partnerships are developing dedicated curricula and tools to deliver real-world industrial experiences in a classroom environment.

Acieta Names New President

Blake Consdorf assumes the leadership role for the division.