Automation/Robotics

Filter by Process Zone:

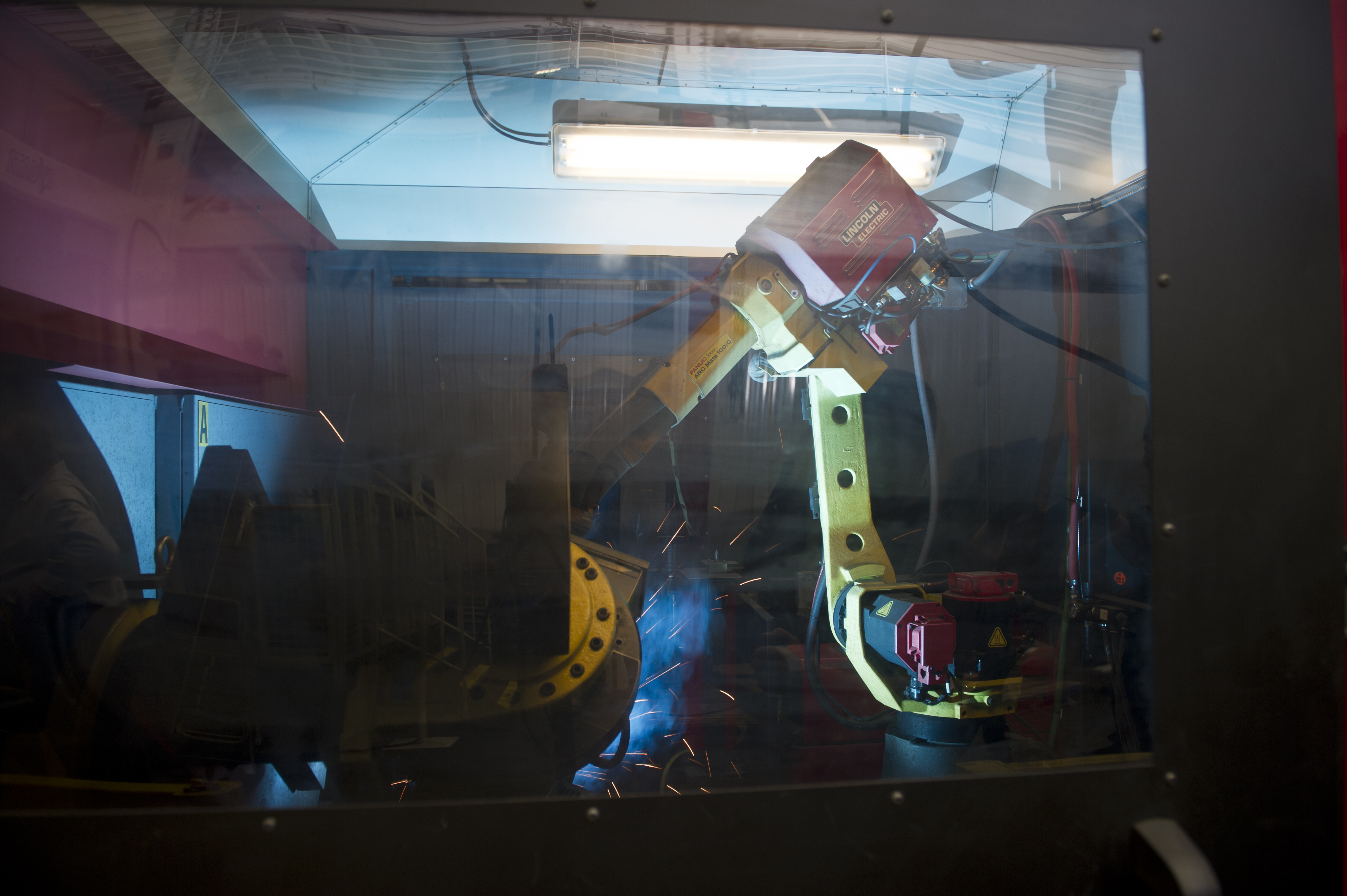

Lincoln Electric Received Certified Robot Integrator Designation

The certification was given after an on-site audit, safety training and hands-on testing of personnel.

Automation/Robotics

Automation is the individual use or integrated configuration of computer software, machines or other technologies ranging from fully mechanical systems to fully virtual networks, very simple to intensely complex in functionality, to carry out a task that would typically be…

Rent a Robot at Miller Electric

The new Robotic Welding Cell Rental Program allows end users to test automation in their own welding operation before purchasing equipment, minimizing risk and barriers regarding capital expenditures, and helping businesses meet short-run production demands.

Jigless Welding: The Next Competitive Edge

In the search for another advantage in an ever-changing production environment, Andrew Swary and John Smith of Miller Welding Automation examine how this method offers shops an alternative for reducing their costs, improving their quality and improving their manufacturing flexibility.

Are Tactile Seam Tracking Systems Right for You?

With the advancements in welding technology, weld travel speeds are increasing beyond manual torch positioning and require some type of automation to achieve greater torch accuracy. Brian Butler of Arc Products explores how seam tracking systems offer this capability with a relatively small capital investment.

What You Must Know About Robotic Welding

Lloyd Steed of Tregaskiss identifies the key factors that must be understood to manage a profitable and productive robotic welding operation that really gains a competitive edge and makes the most out of its investment.

ABB Robotics Showcases Broad Range of Automation Technology

As more plants face skilled labor shortages, Technology Days II featured over 40 live demos and seminars that highlighted automotive and general industrial applications for shops of all sizes looking at automation for competitive advantages.

Welding Robots Justified

The traditional ROI focused on robots as a direct replacement for people. But many fabricators now investing in automation with welding robots eventually hire more people too. What is going on?

ESAB Partners with KUKA Robotics

To support the growth of the robotic welding business in the U.S., this collaborative relationship offers automated robotic arc welding solutions for applications ranging from heavy and light duty welding, to sub-arc, to hybrid laser-arc welding.

Automated Welding Increases Productivity

The Franklin plant of mining equipment manufacturer Joy Mining increased productivity and reduced costs in their bit block assembly by converting to automated welding systems from Lincoln Electric.

Welding with Robot Vision

Weld fixtures not repeatable? Inconsistent weld joints? Robots can now automatically adapt to solve these issues and more. Heath Suraba of Lincoln Electric shares some tips on how to see the best return from your vision investment.

Spot On Welding Control Helps Produce Line of Grills

Outdoor grill manufacturers face considerable foreign and domestic competition, changing demands in public taste and the constant challenge of product innovation. To stay ahead of the competition, the control behind this automated spot welding system provides complete flexibility in producing all of the models, sizes, and quantities they need at any time.