Automation/Robotics

Filter by Process Zone:

FANUC Announces Production of 750,000th Robot

FANUC Corp., a supplier of CNCs, robotics, and factory automation, recently announced the production of its 750,000th industrial robot.

Yaskawa Motoman Accredited Again for its Educational Programs

Yaskawa Motoman’s (Miamisburg, OH) training programs have been accredited for five more years by International Accreditors for Continuing Education and Training (IACET).

Prima Power Laserdyne Contributes Metallurgical Microscope to Technical College in Support of Robotic and Laser Welding Program

Prima Power Laserdyne recently presented a Zeiss high-resolution metallurgical microscope to leaders in Anoka Technical College’s certificate program in robotic and laser welding.

5 Common Questions About Implementing a Robotic Welding System

Proper cable and consumables selection and tool center point (TCP) control play go a long way toward improving quality and optimizing overall equipment effectiveness (OEE). Establish a thorough pre-implementation plan and monitor key issues to get the most of your investment.

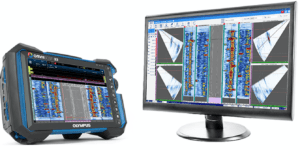

PC Software Maximizes Weld Flaw Detector’s Capabilities

Flexible and customizable WeldSight software for Olympus’ OmniScan X3 phased array flaw detector saves time and effort. In addition to advanced screening capabilities, the program enables inspectors to quickly optimize multiple tools for analyzing complex geometries.

Monitor Ensures Oxide-Free Titanium Welds in Automated Applications

Huntingdon Fusion Techniques’ updated PurgEye 500 Desk weld purge monitor is equipped with PurgeNet. The networking device connects to smart accessories including the drive system for automatic welders and orbital welders and a light accessory for visual warning.

Compact Cladding Cell Accommodates Diameters Up To 3.25 Feet

Fronius has taken a simple, compact solution for cladding applications on smaller parts and developed it for larger tasks. The all-in-one cell’s controls support two processes: TIG hot wire and a two-wire SpeedClad Twin process that’s three times faster.

Ultrasonic Spot Welder Provides Consistent High-Quality Results

Attention, electric vehicle component manufacturers! According to Emerson Automation Solutions, the Branson GMX-20 MA’s dual linear bearing design makes the actuator the most rigid and precise actuator in the ultrasonic metal welding market.

A Primer on Cobotic Welding

More than 20% of commercial welding in the United States is done by a robot, a percentage that will grow as fabricators look for ways to streamline production. Collaborative robots (cobots) make automation a cost-effective proposition even for small shops.

High-Force Actuators Support Robotic Sheet-Metal Welding

Tolomatic’s CSW and CSWX Compact ServoWeld welding gun actuators for robotic spot welding integrate a 3,507-lbf and 4,047-lbf, respectively, actuator into a hollow-core servo motor for faster resistant spot-weld cycles.

Cobot Simplifies and Improves Large-Pipe Welding

Requiring just 4 square feet of shop floor space, Novarc Technologies’ spool welding robot (SWR) enables inexperienced welders working on pipe spools up to 30 feet long to monitor and adjust parameters to pipe variations in real time.

Portable and Easily Adaptable Welding-Automation Solution

Lincoln Electric’s Fab-Pak Cobot Cart enables small- and medium-sized fabricators to justify investing in automation by providing a mobile, easy-to-program, and safe robotic welding solution.