Automation/Robotics

Filter by Process Zone:

Smart In-Process Monitoring of Stamping and Forming Operations

Brankamp X7 “smart” in-process monitoring systems for cold and hot forming, thread rolling and stamping operations from Marposs use AI to quickly monitor machine setups and effectively control machine performance by detecting manufacturing faults, as well as part or tool variations.

Advanced Machine Control and Part Traceability for the Smart Factory

Ideal for IIoT applications, the NX1 controller, HAWK MV-4000 smart camera, handheld HS-360 DPM reader and MicroHAWK ID-45 reader from Omron integrate machine control and part inspection operations seamlessly with quality management and safety systems.

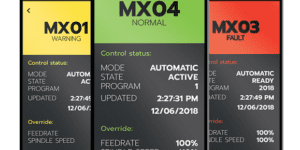

Remote Monitoring of CNC Machines from Handheld Device

Users of the Integrated Machine Analytics mobile app from Mitsubishi Electric Automation can do real-time monitoring and analysis of CNC functions on all MTConnect-compliant CNC machine tools in their facility to keep production on schedule and eliminate potential issues.

Measurement Systems with Open Communications

Diameter, Ovality, Eccentricity, and Flaw Detection measurement systems from LaserLinc use OPC communications protocol that is compatible with Manufacturing 4.0 and IIoT to capture, modify and move data from different systems.

Create A Community for Sharing Metalworking Automation

Using the HKP Mobile App from Haydon Kerk Pittman, technical information and other resources on linear and rotary solutions can be easily shared among colleagues and teams for automation in metalworking, inspection and material handling applications.

Tool Measuring Systems and RFID Working: A Powerful Combination

Efficiently moving information around your shop floor is more important than ever. Connected through RFID, a shop can now use a tool presetter to monitor things never monitored before and use that data to fine-tune processes, reduce inefficient costs like scrap and waste, and make the factory floor smarter, streamlined, far more efficient and competitive.

What Does “Collaborative” Really Mean?

Human-robot collaboration is changing manufacturing operations by helping shops deal with competitive pressures and a lack of skilled labor, but it is not a “one size fits all” solution. Before you invest, consider the different forms of robotic collaboration and how they apply to your entire application.

AAT Partners with DMG MORI USA

DMG MORI machine tools use CappsNC software to perform CMM operations.

Autonomous Machine Vision: The Total Quality Assurance Revolution

Flexible, easy-to-install and affordable visual quality assurance systems can inspect every stage of production, using artificial intelligence to self-adapt and self-adjust to changes. After reviewing samples, they learn – without any human interaction – all of the part’s attributes, surface characteristics, etc. and begin inspecting in only a few minutes.

Robotic Inspection of Weld Defects

Easily interfaced to any robot system or welding machine, the i-FACT intelligent robotic inspection system from Servo-Robot automatically digitizes joint and bead surfaces to provide geometric data and detect weld defects.

How to Give Robotic Grinding and Polishing Processes a Sense of Touch

Ideal for robotic assembly, grinding, and polishing operations, the Axia80 F/T sensor from ATI obtains feedback from force and torque loads as a process is occurring to make robotic and automated processes more acute and responsive.

Robot Performance Measurement and Calibration

To increase robot positional accuracy up to 12X in machining, drilling, grinding, welding, cutting, inspection, deburring and 3D printing operations, the Robot Measurement Solution from API verifies and calibrates robot accuracy to the ISO 9283 standard in a completely automated run-time.