Automation/Robotics

Filter by Process Zone:

Embracing the Robotic Revolution

U.S. manufacturers cannot ignore the growing implications of failing to adopt modern robotics and automated technologies. Rather than fearing the rise of the robot, Americans must further embrace the technology or risk getting left behind in the global manufacturing race.

Fast and Easy Robot Cell Configuration and Deployment

Application Builder from Universal Robots walks users through the entire process of building a successful machine tending, assembly or packaging application with step-by-step guidance on end effectors, programming, machine interfaces and more that is optimized for throughput and cost.

Integrated Robotic Automation of Machine Tools and Assembly

For machine shops that need multi-spindle, high precision machining centers, SW North America can also integrate automated robot cells, assembly systems and turnkey production systems for increased productivity.

Tool Room Cobot

The Cora cobot from Zoller improves tool room economics by automatically picking, assembling, adjusting, clamping, measuring, cleaning, marking and labeling tools in full support of all standard tasks for tool preparation.

Intuitive Cobot Automates Repetitive Tasks

The advanced TM Series Collaborative Robot from Omron boosts production and reduces employee fatigue by safely automating most repetitive production tasks, such as machine tending, loading and unloading, assembly, screw driving, gluing, testing or soldering.

Automation Apps Increase Reliability in Smart Factory Production

Individually configurable software application packages from Liebherr can increase the control and reliability of robotic production in an Industry 4.0 operating environment.

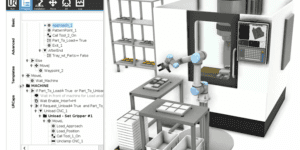

Robot Automation of High-Mix/Low Volume Part Production

To automate the high-mix/low volume operations needed by job shops to compete effectively, Hurco uses fully automated robot systems coordinated by a centralized job management system to connect CNC machining centers with collaborative robots, multi-axis serial robots and pallet systems.

Smart Robotic Part Sorting and Arranging Made Easy

SmartWing robots from Fuji make workpiece sorting, accurate long screw placing, loose part sorting and arranging, and dual robot cooperation for inserting and tightening screws remarkably easy and efficient with accessible automation that virtually eliminates teaching.

Doing Tasks with Robots That Were Not Possible Before

The intuitive Force Guide integrated force control system from Epson Robots enables robots to perform grinding, polishing, part insertion, screw driving and other high precision operations that require high performance motion guidance.

Next Generation Robot Machine Tending

The modular MATRIS robot system from DMG MORI can be paired with turning centers, machining centers and 5-axis machines for flexible machine tending of high precision medical and automotive applications, as well as general machining operations.

How to Give Robotic Grinding and Polishing Processes a Sense of Touch

Ideal for robotic assembly, grinding, and polishing operations, the Axia80 F/T sensor from ATI obtains feedback from force and torque loads as a process is occurring to make robotic and automated processes more acute and responsive.

Robot Performance Measurement and Calibration

To increase robot positional accuracy up to 12X in machining, drilling, grinding, welding, cutting, inspection, deburring and 3D printing operations, the Robot Measurement Solution from API verifies and calibrates robot accuracy to the ISO 9283 standard in a completely automated run-time.