Automation/Robotics

Filter by Process Zone:

When Bigger Really is Better

This machine shop took an unconventional approach to growing into one of the most dependable parts suppliers for a major manufacturer of construction and mining equipment, and now they enjoy a niche that most shops are unable to compete against.

FANUC America to Expand Headquarters

This $51 million expansion will create 100 jobs and be used for engineering, product development, manufacturing and warehousing.

Next Generation CNC and Integrated Factory Automation

The MELSEC iQ-R automation platform on the new C80 Series CNC from Mitsubishi Electric Automation

increases productivity, lowers cycle times and integrates with their IoT systems, FR series robots, 5-axis machining, fully automated manufacturing cell and more.

Plug-and-Play Vacuum End-Of-Arm Tooling for Collaborative Robots

The Collaborative Robot Vacuum Tool from Bimba is a plug-and-play end effector option for collaborative robots that requires no additional software or controls.

Connecting Systems for Intelligent Production

The Connected Machining package of components and systems from Heidenhain supports end users that are introducing digital order management to their production processes to increase competitiveness.

Automation Systems for Economic Small Batch Production

To automate high mix, low volume production operations, Fastems offers the FMS ONE fully configurable machine tool pallet system, Manufacturing Management Software with extended capabilities for controlling robotics, and the Halter Load Assistant compact loading robot cell.

Plug-and-Play Robotic Manufacturing Cells Increase Productivity, Lower Costs

Dual-spindle BA 222 or BA WO2-22 machining centers integrated with a 6-axis robot from SW North America provide high speed machining of complex parts made of non-magnetic materials, watchmaking components, automotive impellers and other precision engineering work.

Unmanned Horizontal Manufacturing Cell for Fast-Paced Machining of Complex Parts

Using a a 20-station APC with work ID system, Automatic Work Handling Robot and 174-tool matrix-style tool changer, the SUPERCELL-300G 5-axis horizontal flexible manufacturing cell from Kitamura Machinery is a space-saving production center that can run small to medium sized, highly complex parts completely unmanned.

Pneumatically Powered Universal Gripper

For use in high temperatures, contamination, aggressive media or for cleanrooms, the nearly maintenance-free PGN-Plus-P universal gripper from SCHUNK accommodates longer fingers and higher workpiece loads.

High Speed, Low-Payload Robots for Material Handling, Machine Tending and More

Fast, flexible and compact RS007N and RS007L 6-axis vertically articulated robots from Kawasaki Robotics offer a maximum payload capacity of 7 kg with excellent functional and environmental performance for assembly, material handling, machine tending and other applications.

AutoCrib Announces New South Asia Partner

AutoCrib South Asia will serve distributors and end users in India, Bangladesh, Bhutan, Nepal, Pakistan, Sri Lanka and other countries in the region.

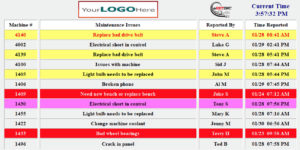

Full Real-Time Visibility of all Facility and Machine Maintenance Needs

Using eNETMD real-time Maintenance Dashboards from eNETDNC, a shop can schedule or prioritize today’s maintenance needs or even weekly, monthly and yearly preventative maintenance projects. It also offers an email server with automated notifications to improve communication within the maintenance department.