Automation/Robotics

Filter by Process Zone:

Automation Systems

The expandable FMS ONE Flexible Manufacturing System, FPC-1500 Flexible Pallet Container system and Multi-Level FMS System from Fastems help shops integrate cells with other plant-wide systems to evolve into a fully digital Industry 4.0 factory.

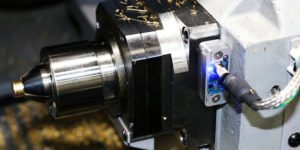

IMTS 2016: Metal Cutting

Come explore the very foundation of the machine tool industry. This pavilion is where you’ll find the latest innovations in metal cutting equipment, machining centers, turning centers, drilling, boring, milling, and more.

An Artillery of Software Automation Tools

Shop Floor Automations will present new software releases for machine monitoring, DNC communication, CNC program editing, document control, and tool management.

Next Generation Safety Certified Robot Monitoring Software

SafeMove2 from ABB Robotics integrates safety features directly into the robot controller, such as cutting-edge safe speed limits, safe standstill monitoring, safe axis ranges and position, and orientation supervision.

New Dimensions in Flexible Manufacturing Systems

In today’s demanding environment, this shop proves how automation has never had so much potential to transform a business.

FANUC America Appoints New President and CEO

Mike Cicco is responsible for all of the company’s operations in North and South America.

Cost Effective Robotic Automation for the Small Shop

The lightweight, powerful, high-speed 6-axis Racer3 articulated robot from Comau features a payload of 3 kg and reach of 630 mm that can be mounted on benches, walls, ceilings or inclined supports.

Machine Enhancement Technology

Hardware and software systems from Caron Engineering provide more intelligent machining that is focused on unattended operation, machine process diagnostics, cycle time reduction, and eliminating operator error.

Large Capacity 6-Axis Robots for Machine Tending

RV-35F, RV-50F, and RV-70F robots from Mitsubishi handle higher payloads requiring longer reaches in CNC machine tending, large material handling jobs and assembly work.

Dynamic Mobile Machine Tending Moves Robots to the Work

Yaskawa Motoman and Clearpath Robotics develop an integrated mobile machine tending and material movement system that is ideal for the shop floor, using a Motoman MH12 robot equipped with end-of-arm tool and vision system mounted on Clearpath’s OTTO 1500 self-driving vehicle.

Robotic Machine Tending Cell for Machine Shops, Job Shops

The affordable VersaCELL Robotic Machine Tending Cell from Versatech helps mitigate the workforce skills gap. It is ideal for shops needing a simple, flexible answer to manpower shortages, inefficient processes and capacity constraints on mid-size CNC lathes, machining centers and grinding operations.

Groundbreaking Innovations in Manufacturing Technology

Mazak will demonstrate new high-level developments in full digital factory integration, smart technology and Industrial Internet of Things (IIoT) connectivity, and new machining and automation systems that prepare shops for the next industrial revolution.