Automation/Robotics

Filter by Process Zone:

Omron Microscan Names New President/CEO

Andy Zosel is appointed president and chief executive officer.

Can We Talk? Conversations Between Machines Get Deep (Part One)

Across the emerging Smart Factory, connected systems are networking production processes from design to final delivery. Conversational programming makes it quick and easy for operators to generate programs at the machine, while other connected systems exchange and use information about tool management, batch processing/scheduling, machine monitoring, quality assurance and more.

Artificial Intelligence: The Next Generation of Communication

Manufacturing generates an unprecedented amount of data, creating an urgent need for shops to augment human analysis with AI that can unlock its value, learn from the historical knowledge embedded in their organizations, and help them remain competitive in the future.

Smart In-Process Monitoring of Stamping and Forming Operations

Brankamp X7 “smart” in-process monitoring systems for cold and hot forming, thread rolling and stamping operations from Marposs use AI to quickly monitor machine setups and effectively control machine performance by detecting manufacturing faults, as well as part or tool variations.

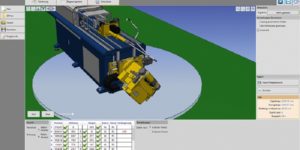

Smart Software Reduces Production Steps

Using a systematic approach to controlled tube manufacturing, t project software from transfluid connects CAD, BDE, ERP and shop intranet systems with tube bending machines and bending robots to make complex tube fabrication simple and safer and production less expensive.

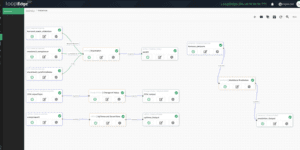

Cloud Communications Connect Machines and Systems for Automation

The LoopEdge computing platform from Litmus Automation can connect to various PLCs, robotic systems, CNC machines, and other industrial systems used for automating manufacturing processes.

A Connected Factory for More Efficient Production Management

Global Release 2019 software from Lantek uses AI, Cloud, machine-learning and other technological advances to obtain quality data for integral control and management of any cutting machine and process with global visibility to raise production levels, increase agility and reduce complexity.

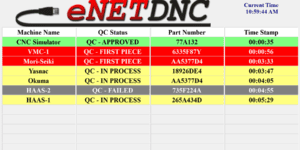

Automated Monitoring of First Piece Inspection on the Shop Floor

Working in conjunction with eNET Machine Monitoring, the eNET QC Status Dashboard from eNETDNC is locally-hosted software that increases visibility and accountability throughout the quality control operation for the first-piece inspection process.

Cybersecurity of Communications Between Controls

By passively intercepting and monitoring serial communications on industrial control networks for intrusion detection and asset management, the SerialTap cybersecurity sensor from Cynash helps shops address and solve complex security challenges that affect their legacy control systems.

Automatic Data Analysis Increases Shop Floor Efficiency and Reduces Downtime

ShopFloorConnect 6.0 OEE and Shop Floor Data Collection software from Wintriss Controls gathers production data from every machine in the factory, displays the Key Performance Indicators in real-time and produces detailed analytics, including comprehensive OEE reports in a variety of formats.

Secure Transfer of Process Data to Mobile Devices

TwinCAT IoT Communicator software and the IoT Communicator App for tablets and smartphones from Beckhoff Automation uses advanced encryption and protocol for easy mobile device integration and high-level communication security.

Sensors + Software = End-To-End Internet of Things

The Connected Data Solutions Platform from Banner Engineering allows users to easily and securely transmit and use remote data from cloud-connected devices to monitor shop productivity, predict machine maintenance requirements and make operational decisions on machine performance.