CAD/CAM Software

Filter by Process Zone:

New THOR F Combines High Performance Thermal & Mechanical Cutting

THOR F integrates plasma and oxyfuel cutting with an optional beveling system, and an optional tube and profile lathe. It also combines plate cutting with edge preparation and numerous mechanical machining operations, including milling, drilling, tapping, countersinking, marking, etc.

Automated 6-Axis Structural Steel Robotic Beam Cutting Machine

The Beamcut System 3D Robotic Profile Cutting Machine cuts any shape from mild steel, stainless steel, and aluminum with high repeatability and accuracy. It eliminates costly layouts and grinding, simplifies fabrication, minimizes errors, and boosts production speeds.

New 3D Printing Software Unlocks Full Transparency and Control of Parameters

Velo3D’s Flow Developer: From black box to full transparency and control, the new product enables a pathway to migrate additive manufacturing knowledge to VELO3D’s fully integrated solution and print process optimization.

Calculate Sheet Metal Parts Faster

New export function for precise geometry analyses and optimized cost

calculations of sheet metal parts.

Empowering Efficiency with Enhanced Features: ProNest 2025 CAD/CAM Nesting Software

The latest version of ProNest from Hypertherm Associates features an optional module that offers enhanced integration with Tekla PowerFab Connector.

New Robotic Bending Cell Offers High Amount of Flexibility

LVD Co. adds the Easy-Cell 80/25 to its line of robotic bending cells. The product combines an Easy-Form 80-ton press brake with a KUKA industrial robot, and is equipped with the Easy-Form Laser for bend accuracy.

Sheet Metal CAD/CAM and ERP Software Enable Substantial Productivity Gains

Lantek helps deliver substantial productivity improvements for Australian sheet metal manufacturer with technology available in North America.

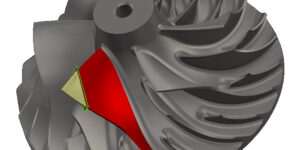

The Sum of Its Parts: CAM Plus Additive Equals Powerful Hybrid Manufacturing

A manufacturer that has both subtractive and additive manufacturing capabilities may be better prepared for whatever jobs come along.

Davi: Trusted Partners Revolutionizing the Plate Roll Industry

Davi Inc. continues to invest heavily in research and development to develop new solutions in plate roll and angle roll machinery.

Machining: Optimize the Solutions

Discover what’s next for machine tools. It may be just the time to update your shop’s metal removal technologies and processes.

Ultra-High-Power Lasers Tackle Ultra Heavy Plate

With more than 20 kilowatts of power available, cutting thickness limits can be pushed to as thick as 2”, allowing fabricators to bring the speed, precision and cutting quality of the laser to a new range of parts and products.

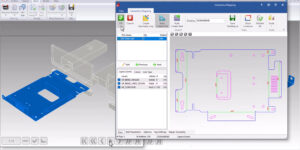

SigmaNEST 24 Suite Connects CAD/CAM, Shop Floor and Business Systems

SigmaNEST, is pleased to announce version 24 of the software suite. The new release gives fabricators the tools to reach higher productivity throughout the shop, while being easy and intuitive to use. SigmaNEST 24 suite helps users in three ways: Deeper software integration, a more effective UI, and CAD/CAM enhancements that drive predictably high-quality output at the machine.