Clamps

Filter by Process Zone:

Röhm Expands Sales Team

Steven Onik is their new national sales manager and Yusuf Ali is their regional sales manager for Canada.

Quick Die and Mold Change Catalog

This new edition from Hilma Carr Lane Roemheld features a variety of clamps and lifters, cylinders, power units and valve packages, and showcases their line of magnetic clamping systems for plastic and rubber molding machines.

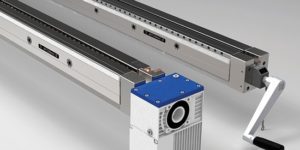

Crowning Deflection Control System for Press Brakes

The Express Crowning system from Wilson Tool helps control deflection or “the canoe effect” in press brake applications over 4 ft long with quick, repeatable crowning that is precisely adjusted by a basic hand crank and digital readout or an electric motor driven by the CNC machine control.

Röhm Appoints New Regional Sales Managers

Mark Thompson, Josh Vanderveer, and Jonathan Napier have joined their sales team.

Whittemore Expands Sales Territory

They now serve Kansas and Missouri with tools for metal cutting, broaching, gauging, workholding, part marking and managing swarf.

Hoffman Group Recognized as Key Automotive Supplier

Brose honors them for outstanding tool quality, cost, on-time delivery and innovation.

Injection Mold Clamping Magnets

Using proximity sensors for accurate positioning, injection mold clamping magnets from Techniks can be installed right over the existing platens to reduce set up time and take up less space, leaving room for fitting larger molds.

New REGO-FIX Facility Wins Builder an ABC Award

Wurster Construction was honored for their work by the Associated Builders and Contractors of Indiana/Kentucky.

Energy Efficient Electro-Mechanical Clamping Reduces Costs

Powered by electricity instead of hydraulics, e-QUIPMENT steadyrests, clamping heads, grippers, cylinder systems (with and without through holes) and tool locking systems from Röhm only require energy during actuation and electrically manage adjustments of clamping forces and strokes during operation.

Modular System Specifically for Direct Workpiece Clamping

With basic modules, clamping modules and stacking modules that can all be freely combined, the VERO-S WDB system from SCHUNK uses clamping pillars with a modular structure to clamp freely-molded parts and other workpieces directly on the machine table without the need of additional equipment.

How Modular Workholding Increases Overall Spindle Utilization

Want to take the headache out of machine setups for high mix runs that are frequently made from tough materials, demand extreme precision and high quality surface finishes? Modular palletized workholding revolutionizes the alignment process by reducing set up times up to 90 percent, providing safe clamping forces, tighter tolerances, and higher transfer repeatability.

Pneumatic Saw Cuts Steel Plate, Pipe and More Without Heat Affect Zone

Ideal for on-site fabrication of structures, tanks, ships and related equipment, the APS-438 Air-Powered Saw and Quick-Clamp from ESCO Tool sets up fast using a 2 in W steel track and two wedge-style clamps that attach to steel plate up to 15 ft W by 3.5 in thick and accept the saw.