Coil Handling Equipment

Filter by Process Zone:

COE Press Equipment Announces New Purchasing Manager

Coe Press Equipment (Sterling Heights, MI) has announced the appointment of Douglas Thedford as its new purchasing manager.

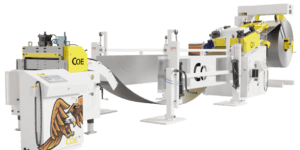

COE Press Equipment Will Feature Coil Processing Equipment

At Booth D46924, COE Press Equipment (Sterling Heights, MI) will display a 24” wide Servo Roll Feed with its patent-pending Series 406 4.00” × 24” Straightener with 4” pinch rolls.

Heavy-Gauge Straightener for Heavy Vehicle Component Manufacturers

Automatic Feed’s heavy-gauge straightener processes coiled steel up to 78 inches wide and a half-inch thick at speeds of up to 150 feet per minute. The machine’s performance results in consistent quality, reliability, and accuracy.

Double-Duty Brush Washers Clean and Lubricate Before Stamping

Handling material up to 84 in. wide, Automatic Feed’s coil-fed lubricant brush washers continuously clean debris while an automatic grease system lubricates the roll bearings. Result: great surface quality and reduced downtime for maintenance.

Updated PLC Controls Cut Setup Time in Half

Simulation and automated functions expedite commissioning new press feeding lines from COE Press Equipment. User-friendly interface and 10-in touchscreen simplify entry of machine setup information as well as troubleshooting.

Multiblanking System Combines Work Steps in a Single Run

b+s group combines cut-to-length and slitting lines at a speed of up to 100 m/min. The time-saving process also incorporates inspection measures that make this sheet metal processing suitable for sensitive surfaces like stainless steel and aluminum strips.

Cassette Levelers Achieve Superior Flatness

Automatic Feed’s three new models handle many material types as well as a range of widths, thicknesses and yield strengths. Gearboxes powered by AC servo-driven motors help achieve high precision and accuracy.

Dynamic Scrap Handling Increases Coil-Fed Laser Blanking Speed

Coil-fed laser blanking systems from LaserCoil rely on a series of dynamic profile conveyor lanes that independently adjust, reposition and automatically shed scrap to maintain a clear path for the cutting process.

New Sales Manager at COE

Dave Byer is their new national sales and marketing manager.

AFCO Appoints New Customer Relations Manager

Jon Knepley now leads their customer service efforts.

Automatic Feed Hires New Technical Buyer

Jarrett Beck evaluates supplier products, services and pricing for their sourcing needs.

Roll Coater Lubrication for Tough Stamping Environments

The extremely rugged Minicoater roll coater lubrication system from LSP Industries dispenses precise amounts of fluids through a unique built-in manifold system when the press cycles for partial strip lubrication and top and/or bottom-only lubrication.