Coil Handling Equipment

Filter by Process Zone:

Industrial Innovations Expands Sales Network

Shawn Hagen of Nidec Press & Automation now represents them in Illinois and Missouri.

Tenneco Installs New Lubrication Equipment

The two lubrication systems from Industrial Innovations are used in the pressroom of their Elkhart, IN, automotive plant.

Steelscape Wins 2018 NCCA Safety Award

They are recognized for their unparalleled long-term safety record.

Industrial Innovations Expands Sales Network

Die Maker Solutions now represents their lubrication systems for metal stamping and forming shops in Texas and Oklahoma.

Accurately Pinpoint Bottlenecks and Inefficiencies in Coil Processing Lines

The Time Tracker System from Red Bud Industries is a production monitoring system with an organized, easy-to-use interface a supervisor needs to monitor multiple coil processing lines in a single factory or several locations.

One-Stop Portfolio of Coil Processing Solutions

The extensive range of coil processing systems for pickling, lubrication, cleaning, pretreatment, passivation, coating and lamination from Henkel are specially formulated for high speed, continuous operation, greater cost efficiency and sustainability of manufacturing lines.

Mechanical C-Frame Press for Blanking, Punching, Forming, Coining and Deep Drawing

The T63 RCE Mechanical C-frame back geared press from Sangiacomo Presses uses an intermediate reduction gear to provide higher tonnage at reduced nominal speeds and the adjustable stroke helps achieve higher productivity, better component quality, longer die life, and increased flexibility.

Goodman Installs Ten Coil Feed Lines

The lines from COE Press Equipment are used to build HVAC equipment in the Daikin Texas Technology Park facility.

Upgraded Feed Line for Progressive Die Operations

The UnderLoop SpaceSaver from Dallas Industries is a reconfigured threading system featuring a servo-driven synthetic tension roll, UnderLoop lower threading table and rocker arm, and de-bending assembly.

How to Defeat Downtime

No one is happy when a machine goes down because of tooling issues – wasted time that is even more frustrating when it’s avoidable. Arrow Storage Products found a way to significantly reduce their machine downtime and cut their average tooling downtime per week due to tooling by 70 percent.

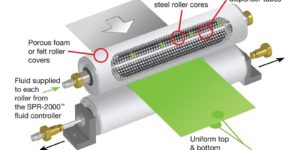

Stock Lubricator Delivers Cleaner Floors and Presses, Reduces Lubrication Costs

With improved guarding that helps guide material when loading coil stock or feeding blanks, the updated Uni-Roller stock lubricator from Unist delivers 50 percent or better reduction in lubricant consumption for cleaner floors and press windows.

Coil Lubricating System for Stamping Improves Accuracy and Reduces Costs

The Spra-Rite UltraCoat non-contact spray system from Industrial Innovations is designed for easy coil feed installation and press control communication for reliable, economical application of lubricant to stock prior to stamping to help improve accuracy and reduce overspray and consumption.