Collets

Filter by Process Zone:

Tool Holder Systems for All Applications

This comprehensive 296-page catalog of BIG Daishowa high-precision tool holder systems from BIG Kaiser is a single source for all tool holder needs and is organized by spindle interface for easy browsing and effortless navigation.

Put On Hold

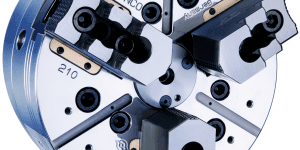

The increase in higher precision machining is creating demand for stronger, more durable, faster acting, closer tolerance chucks and collets that can grip and hold the parts and the tools being used. Here is a review of some of the latest chuck and collet solutions that meet that demand.

Flexible Collet Chuck Is Ideal for Job Shops

The Mega ER Grip with the modular KAB connection from BIG Kaiser outperforms other systems in clamping force, concentricity, rigidity and balance at high spindle speeds.

Shaving More Seconds Off Quick Changeover

Take a look at how this job shop uses a highly versatile modular quick change collet system to perform setups and changeovers in speeds of 15 seconds or less.

KOMET and SCHUNK Hold Joint Distributor Event

The five-hour event included demos of SCHUNK workholding and toolholding working together seamlessly with KOMET cutting tools in a machining center on the production floor.

Anti-Pull System Eliminates Cutter Pullout in Demanding Applications

The secuRgrip anti-pull system from Rego-Fix Tool is ideal for aerospace machining of expensive castings and materials or complex parts.

Vulcanized Collet Systems are Ideal for Job Shops

The quick-change 80 mm FlexC™ vulcanized collet system from Hardinge guarantees accuracy within .0004 in TIR for style A (pull-back Dead-length® stationary stop) and .0008 in TIR for style DL (push-to-close).

End Mills with Clamping Interface Boost Productivity and Precision, Reduce Scrap

The Haimer Safe-Lock™ clamping system is now part of specially modified Walter Prototyp solid carbide mills from Walter USA..

EXSYS Strengthens Customer Service Team in Canada

The company hired Lisa Medica as office manager and Kelly Bruce as inside sales representative at its Brampton, Ontario

location.

REGO-FIX® Honored with Award by Swiss Venture Club

The tooling manufacturer received the prestigious Prix SVC award for excellence in innovation, business performance and sustainable development.

U.S. Manufacturers Tour Kaiser Switzerland

Visitors on the tour were shown a 30-year-old tool body that had just been returned by a manufacturer for repair work. Operations from product and fixture design to rough and finish machining and assembly are done on two levels of the original Kaiser factory. A flexible production process supports lot sizes from one to 1,000, but typical lots are 10 to 150 pieces.

Exporting the BIG KAISER Model to Europe

KAISER announced its three-year plan, including its fortified relationship with BIG Daishowa, during the company’s recent 65th anniversary festivities.