Cut-To-Length Lines

Filter by Process Zone:

Tolerances in Tube Bending

How tolerances are used in tube bending and why they matter.

Trilogy Machinery’s Processes and People Ensure Your Success

Stocked with metal fabrication machines ranging from entry level to custom designed, and full parts and service departments, Trilogy Machinery collaborates with customers to determine the best solutions for their applications.

Increase Your Productivity with Highly Precise and Accurate Solutions

The most innovative and updated features to today’s metal forming and fabricating machinery, additive manufacturing equipment, software, controllers and accessories result in efficiencies — both in production and cost savings.

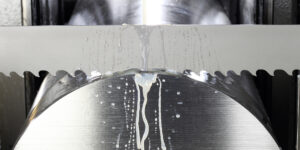

Rugged Frame and Table Ensure Vertical Toolroom Saws are Productive and Versatile

The saw can easily handle contour sawing, beveling, slicing, ripping, stack cutting and cutting off various materials from aluminum, brass to steel.

Transformative, Precise and Fast-moving Cutting Systems Expand Opportunities

No matter what your project calls for, there is an advanced cutting equipment solution to enhance and expand your metal fabrication capabilities.

Next Level Sawing

Breakthroughs in the development of robust sawing systems ensures your shop will exceed your customers’ most challenging and unique demands.

Fast Automated Bending Solution for Tall, Thick Parts

New TRUMPF TruBend Center 7020 offers highest box height of any commercially available panel bending machine and reduces cycle time by up to 80% compared to manual press brakes.

Automatic Dual Column Saws Provide Many Advantages That Increase Efficiency

Automatic dual column band saws from Cosen Saws are designed to meet the demands of modern manufacturing, service centers, and fabrication industries.

Clean Tube Technology, also Known as a “Spoon,” Option for Lasertube Machines

This option, which is available for BLM Group’s lasertubes 8” and below, helps produce a clean and dross-free internal finish.

Entry-level Sheet Laser Cutter has Features of High-end System at Attractive Price

BLM GROUP’s new LS7 can cut steel, stainless steel, iron, copper, brass, and aluminum in thicknesses from 0.20” to 1.57”, or even double sheets.

Introducing RoboRail, an Affordable All-In-One Robotic Plasma Cutting Machine

HGG’s RoboRail incorporates advanced robotic tech to process a vast range of materials quickly and accurately to length.

Multiblanking System Combines Work Steps in a Single Run

b+s group combines cut-to-length and slitting lines at a speed of up to 100 m/min. The time-saving process also incorporates inspection measures that make this sheet metal processing suitable for sensitive surfaces like stainless steel and aluminum strips.