Cut-To-Length Lines

Filter by Process Zone:

Worthington Specialty Processing Orders LaserCoil Blanking System

The 2,100 mm wide dual-head system features two 6 kW lasers that challenge traditional mechanical presses by expanding the production capacity of Advanced High Strength Steel blanks.

TMW To Build Toll Processing Center at Big River Steel

The new 110,000 sq ft facility will add 45 new jobs and have cut-to-length and slitting lines that can process light gauge to plate materials.

Paxton Vierling Steel Acquires Cut-To-Length Line

The steel service center ordered a Heavy Gage Cut-To-Length Line from Red Bud with an adjustable stretcher leveler that produces significantly better length and quality.

United Performance Metals Houston Earns ISO Certification

The metal service center has met the standards to supply, process, stock and distribute stainless steel and high temperature alloy plates for the aerospace, petrochemical, and commercial markets.

COE Press Equipment Appoints CTL Business Manager

Benjamin T. Pauzus is now responsible for day-to-day management of the CTL business, as well as sales and marketing leads where he will help to establish new customers and sales channels.

ThyssenKrupp Materials NA Opens $15M Coil Processing Facility in Alabama

The 100,000 sq ft carbon, stainless and aluminum coil processing and distribution service center currently employs 20 full-time positions. At full capacity, the facility will create nearly 45 full-time jobs.

Material Works Announced EPS Technology Has Been Approved

Material Works announced that strip steel processed by the Eco Pickled Surface technology has been approved as a replacement for acid pickled steel by the automotive manufacturers General Motors and Chrysler.

Fabtech 2013: Coil Processing, Press Room Equipment

A look at some of the coil handling systems, cut-to-length lines, slitting lines, hydroforming, stamping presses and other press room equipment exhibited on the show floor at McCormick Place in Chicago on November 18-21.

Coil Handling Lines for Metal Stampers

CHS Automation/Pneumatic Feed Service displays an assortment of coil handling lines for metal stampers, including advanced servo feed rolls, straighteners, coil reels, cradles, air feeds and other equipment.

Laser Blanking Line

The new laser blanking line from Schuler Incorporated combines cutting-edge laser methods with continuous coil feeding for maximum performance and flexibility, utilizing DynamicFlow Technology that is energy efficient and can process a variety of materials such as high-strength steels, with repeat accuracy and edge quality. The new line cuts blanks from a continuously fed aluminum coil. Using three laser heads in parallel, this blanking line can cut blanks with a thickness of 0.8 mm to 3 mm and a width of up to 2,150 mm.

Advanced Slitting System for Multi-Blanking and Slitting Lines

The new Fully Automated CNC Programmable Slitting Head from Red Bud Industries is a highly advanced Slitting System for both Multi-Blanking and Slitting Lines with a Head that is fully automated to completely set itself up without any operator intervention in less than two minutes.

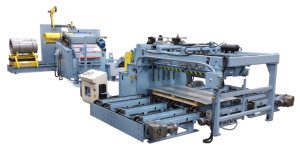

Advanced Roll Feeding, Cut-To-Length Systems

COE Press Equipment highlights their Cut-to-Length Line (CTL) that provides fabricators and metal stampers with cost savings associated with producing blanks in-house, along with a conventional coil line featuring its ServoMaster SM2-18 Zig-Zag Roll Feed.