Cutting Tools

Filter by Process Zone:

Digital-Ready Boring Tools Simplify Precision Adjustment

Frustrated by losing count of how far the adjustment screw was turned when dialing in a tight bore? Kennametal’s eBore Fine Boring System keeps track of boring bar movement for you. End result: less scrap, less downtime, and faster setups.

Defined Chamfering Deburrs Gear Teeth In Seconds

To enable high-volume gear production, Horn USA will develop a carbide milling tool and machining program to produce defined chamfers based on material and gear tooth geometry. The service quickly pays for itself and doesn’t require special workholding.

Increase Productivity When Machining Heat-Resistant Super Alloys

Unpredictable tool life and slow rough-machining speeds hinder heat-resistant super alloy (HRSA) component productivity. New Secomax CW100 silicon carbide whisker-reinforced ceramic insert formats and geometries successfully tackle materials such as Inconel 718 and Hastelloy.

Inserts Support Both Unmanned Production and Custom Components

Sandvik Coromant uses a second-generation chemical vapor deposition (CVD) alumina coating to produce two turning grades – GC4415 and GC4425 – that withstand the extreme temperatures of P25 cutting zones during continuous operations.

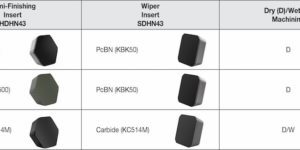

Face Mill for Multiple Cast Iron Applications

Kennametal’s KCFM 45 is a flexible, cost-effective, and user-friendly face mill for gray cast iron, CGI applications, semi-finishing and fine-finishing operations on any type of CNC machining center. Produces surface finishes of 0.8µm Ra (32 µin.) or better, and waviness lower than 10µm Wt (400 µin.).

All-in-One Tool Cuts Machining Time by 25%

Ceratizit’s FreeTurn tools enhance milling machine productivity by combining multiple-propertied inserts with variable approach angles. The spindle rotates the cutting surface 360 degrees to perform roughing, finishing, contour turning, facing, and longitudinal turning with one tool.

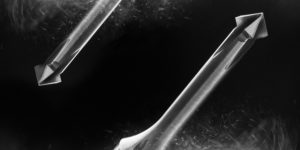

Time-Saving Dual-Purpose Milling Cutter

Big Kaiser’s Noventa from Sphinx is ideal for 90-degree front and back chamfering, and deburring holes up to 4xD. The milling cutter’s design also delivers a surface that feels like a finished product that’s safe to handle.

Two High-Speed Solid Carbide Milling Cutters

The MC025 Advance and MD025 Supreme cutters from Walter feature high cutting speeds, exceptional reliability, and universal applicability.

Double Turbo Square Shoulder Mills and Inserts

Improve roughing operations and achieve superior surface finishes without high machine power consumption with Seco Tools’ Double Turbo line of cutters. Double-sided inserts and superior milling grades significantly lower finishing cycle times.

Rough and Finish with One Tool

Sandvik Coromant’s M5C90 milling cutter resolves the challenges of machining lightweight aluminium by roughing and finishing in one pass cylinder heads, cylinder blocks, and other automotive components formerly made from heavier cast iron alloys.

Full Speed Ahead For Every Milling Job

Hoffmann Group expands its family of high-feed-rate milling tools with the Garant Power Q Double all-round system. Three-part cutting edge increases reliability and productivity by reducing cutting forces and optimizing chip evacuation.

Cutting With A Purpose

Founded in 1896, Bico Steel prides itself on being a value-add supplier of steel plate and forged steel blocks. Switching bandsaw blades helped the Michigan company prove its worth when asked to quickly deliver product for ventilators early in the pandemic.