Cutting Tools

Filter by Process Zone:

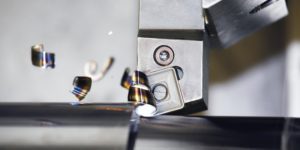

New Chip Breakers and Grades for Indexable Turning and Milling

The positive stable geometry of the HR2 chip breaker from Dormer Pramet increases productivity in steels, cast irons and stainless steels with reliable chip formation and evacuation at high feeds.

Solid Ceramic Endmills Provide Stellar Performance

To deliver Inconel parts on time with zero scrap, this aerospace supplier uses 4-flute and 6-flute end mills constructed of SiAlON KYS40 grade ceramic for roughing nickel-based high-temperature alloys.

Fulfilling Modern Micromachining Demands on a Legacy Machine

Looking for a creative way to achieve the requested specifications for a potentially lucrative micromachining job without having to invest in a very expensive specialized machine tool? A spindle speeder may be your best – and only – way to secure the deal.

U.S. Cutting Tool Orders Slip in April

Caution about sluggish growth as U.S. cutting tool consumption fell to $173.6 million for the month.

Razor Tool Opens New Facility

Beyond specials, regrinds, and high performance standard cutting tools, their new plant also offers high-precision five-axis machining to help shops with challenging jobs.

Double-Sided, Multi-Edge Milling for Large Batch Production

The unique positioning of the tilted inserts in the CoroMill 745 from Sandvik Coromat is ideal for roughing to semi-finishing steel and cast iron materials in all types of milling machines.

U.S. Cutting Tool Orders Up Slightly

March orders of $184.08 million were up six percent over the previous month.

Coolant-Through Tooling

By targeting the coolant stream as close to right place in the cutting zone as possible, coolant-through tooling systems can bring improvements that range from higher cutting speeds to better surface finish by effectively controlling chips and helping to optimize tool life and increase production. Here are some of the latest systems to consider.

Coolant-Through High-Feed Face Mills and End Mills

Coolant-through ready cutter bodies from Techniks are made from high grade H13 tool steel that is precision ground for accuracy and feature an electroless nickel coating for longevity and rust resistance.

Coolant-Through-The-Tool Drilling

Using the reCool attachment from Rego-Fix Tool on Suhner feed drilling units can increase surface cutting speed by 20 percent for higher chip removal rates and drastically reduced machine cycle time.

Over and Under Coolant Helps Increase Machine Utilization for Effective Steel Turning

The unique CoroTurn 300 insert from Sandvik Coromant has excellent chip breaking capabilities and less carbide per edge to reduce the impact on the environment with less material to waste or recycle, and more edges for better inventory control.

Powerful, Directed Coolant Boosts Productivity, Tool Life and Surface Finish

The Turn Precision Coolant delivery system from Walter increases tool life by 30 percent to 150 percent when machining stainless materials, high temperature alloys and steels.