Deburring Machines

Filter by Process Zone:

Vibratory Bowl Features Easy Media Discharge Chute

Burr King’s VibraKing 200c 20-quart bowl includes a patent-pending chute plug with double seals that guard against leaks during operation. Use for deburring and more in both wet and dry processing.

Deburring for Applications with Tight Tolerances and Heat Sensitivity

Unlike conventional grinding, wire EDM, and lasers, Tridex Technology’s SG-1645 and SG-2060 electrochemical grinders quickly provide a burr-free cut in one pass with no heat-affected zone, recast layer, or work hardening of the material. Arthroscopic shaver teeth are commonly produced by conventional abrasive grinding, wire EDM, or laser cutting, but each method has disadvantages.

Compact Deburring and Edge-Rounding Machine

With its 9-inch-wide footprint, Midwest Automation’s Mighty 9 finishing machine fits virtually anywhere on a shop floor. Fixed belt (FB), adjustable belt (AB), and top brush (TB) abrasive head assemblies provide flexibility by allowing multiple combinations.

Updated Machine Allows Lights-Out Deburring and Chamfering

Helios Gear Products adds CNC capability to Tecnomacchine (TM) deburring and chamfering machines to improve repeatability, programmability, and ease of use. The TM 1000-CNC’s 8 axes and two spindles handle parts up to 40 inches (1 meter) in diameter.

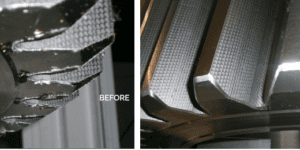

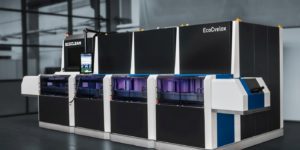

Part Deburring, Cleaning, and Drying On A 15-Second Cycle

Combining high-pressure water jet deburring with low-pressure part cleaning and drying processes, the EcoCvelox from Ecoclean Inc. is a one-stop finishing solution. Highly configurable equipment enables highly flexible process design.

Best Practices For Avoiding a Burr in the Saddle

Deburring ensures parts fit perfectly during welding or final assembly. This leads to higher-quality products and more efficient workflows that will save your shop time and money – and improve its bottom line.

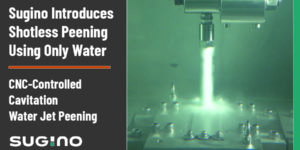

Peen and Wash Simultaneously With Shotless Process That Uses Only Water

Sugino Machine adds waterjet peening with up to 5-axis CNC control to its lineup of equipment that uses water to atomize, deburr, and clean. Peen inside holes, tubes, and cavities without masking or the waste and mess of standard shot peening.

An Introduction to Robotic Cutting, Deburring, and Finishing (CDF)

Improvements in finishing tools over the last decade have opened the door to productivity-enhancing automation. Here are solutions manufacturers can confidently implement today.

Versatile Deburring Tool Replaces Manual Material Removal Processes

For cobot applications in light and medium deburring, chamfering and scraping operations, the pneumatically-actuated Compliant Deburring Blade from ATI Industrial Automation excels in both axial and radial compliance to produce consistent results where surface irregularities are present.

How to Increase Speed in Downstream Processes

Process quality on parts coming off the EdgeBreaker 3000 deburring machine and FlatMaster 55 precision leveler from ARKU allows increased speed and reliability during downstream welding, bending and forming processes.

A Breakthrough in Beveling

Providing consistent bevel geometry from end-to-end, the self-propelled ABM 50 Double-Sided Beveling Machine from Steelmax quickly inverts to produce double-side bevels without having to flip the plate, improving safety and reducing material handling time and expense.

How to Easily Automate Manual Material Removal Jobs

With the versatile Compliant Deburring Blade from ATI Industrial Automation, users can easily automate manual light and medium deburring, chamfering, and scraping operations on materials such as plastic, aluminum, steel, and brass.