Drilling Machines

Filter by Process Zone:

Tackle More Steel Fabrications Jobs with One Tool

Using a #2 Morse Taper arbor system, the HMD2MT portable magnetic drill from Hougen can be used for tapping holes, reaming to clean or enlarge holes, drilling blind and smaller holes, and countersinking.

Concurrent Gundrill Grinding and Measuring for Faster Speed, Absolute Process Repeatability and Accuracy

The software, hardware, high precision fixturing and measuring capability of the Gundrill Grinder from UNISIG enables concurrent grinding and measuring operations that ensure absolute process repeatability and accuracy, and faster grinding speeds.

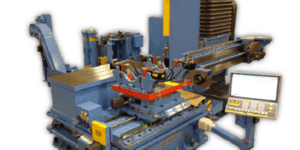

Gun Barrel Drilling and Reaming on One Machine

The twin-spindle DeHoff G560-DR2 machine from Kays Engineering has a drilling capacity of 17 caliber to 50 caliber with a slide travel of 60 in and performs both gundrilling and reaming operations on gun barrels.

Modular Systems for Custom Profile Machining

Special modular systems from Suhner can be created for complete profile machining applications of various large volume parts or long sections from multiple sides that often fit poorly or not at all on standard machine tools.

Effective Drilling of Complex Hole Patterns

The redesigned DeHoff 2072TC gundrilling machine with 5-axis capability from Kays Engineering mounts a gundrilling spindle on a traveling column for X-axis and Y-axis movement, with a CAT 40 spindle mounted on the traveling column for secondary milling and tapping operations.

Large Turbine Engine Component Machining for Power Generation

Equipped with a 2-axis rotary table for enhanced workpiece positioning, the EDBV8 fast hole EDM drilling machine from Makino provides blade and vane manufacturers with the flexibility to accommodate a wider range of part sizes for any high volume fast hole EDM drilling application.

Drill Press with Hybrid Mill Function

The 3MT Spindle and ER32 Collet System on the NOVA Vulcan Metal Working Drill Press from Teknatool combine for maximum holding flexibility, while its machine tool spindle-specified double-row angular contact bearings deliver rigidity for the side thrust pressures of milling.

Milwaukee Tool Expands in Three Mississippi Locations

They are investing $33.4 million and creating 660 jobs at their sites in Greenwood, Jackson and Olive Branch.

Deep Hole Drilling of Diesel Engine Components, Transmission Shafts and More

To increase the manufacturing capacity of diesel engines, the compact UNE 12-2 gundrilling system from UNISIG easily installs in existing CNC machining cells and uses real-time process monitoring of thrust power, coolant pressure and more to create ideal temperatures on the cutting surface and eliminate thermal damage to parts.

Portable Multi-Functional Mag Drill with Automatic Feed and Reverse for Large Holemaking

With adjustable automatic feed and power retraction and an integrated automatic cooling/lubrication system, the portable MAB 1300 V mag drill from CS Unitec is suitable for production applications and can tap large holes up to 1-5/8 in diameter.

Lightweight Ultra-Low Profile Mag Drill for Confined Spaces

The compact HMD130 Portable Magnetic Drill from Hougen features a bayonet-style twist and lock cutter mounting system and a height of only 6-11/16 in that is small enough to drill in confined spaces where even handheld electric drills can’t go.

Machining Center for Fabricators Boosts Profit for Any Shop

Ideal for milling, drilling, tapping, beveling, countersinking, and form drilling large 20 ft parts on a single setup, the FlexDrill CNC Machine from FlexArm uses a variety of smart fixturing to eliminate spindle downtime, remove bottlenecks, maximize productivity and boost profit for any shop.