End-of-Arm Tooling

Filter by Process Zone:

Robotic Grippers for Efficient Tending of Metal Fabrication Operations

The RG2 Collaborative Gripper and the VG10 dual-zone electrical vacuum gripper from OnRobot provide dual grip capabilities, flexibility and more to optimize handling and cut machine tending time.

OnRobot Opens First R&D Office in U.S.

The new location in Los Angeles provides opportunities to attract talent and expand their robotic gripper portfolio.

Metal Handling is Only as Good as its EOAT

End-of Arm Tooling systems from Piab optimize the precision handling of difficult loads, from repeatable blank transfers and placements in press stamping to vertical and horizontal pick-and-placing of spools, machined parts, pipe, large gears, barrels and more.

Grippers Assembled in the U.S.

SCHUNK shortens their lead times and can customize tooling applications by using standard on-hand components.

A Gripping Display of Automation Technology

Crowds gathered recently for a day of education and networking in automation technology that was co-hosted by ATI and SCHUNK.

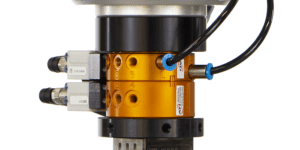

First Automated Tool Changer Certified in Americas for UR+ Program

Universal Robots certifies the QC-11 Automated Tool Changer from ATI as the first automated tool changer developed in Americas for the UR+ platform to work seamlessly with UR cobots.

Kitagawa North-Tech Reorganizes Sales Staff

Shawn Luschei is vice president of sales and marketing, Dale Anderson is inside sales manager, and Ryosuke Yatsunami is business development manager.

This Gripper IS Rocket Science

Built with NASA-created technology, the unique Gecko Gripper from OnRobot is a cost-efficient alternative to vacuum systems, replacing compressed air with tactile technology that adhere to surfaces the same way that geckos climb.

Air Tools Designed for Cobots

Outfitting a cobot from Universal Robots with a Dynabrade sander can automate and streamline repetitive or potentially unsafe processes to increase productivity, reduce injury and provide consistency of finish at all levels of production.

Plug-and-Play End-of-Arm Vacuum Tooling for Cobots Improves Productivity

The flexible piCOBOT end-of-arm-tool from Piab is designed for maximum flexibility and reach with 3.8 in to 5.6 in wide, ±15 deg tiltable gripper arms that can be fitted with two suction cups. Alternatively, the gripper can be replaced by a single suction cup mount directly on the cobot’s pump unit.

Change End-Of-Arm Tooling on Cobots in Seconds

With the lightweight Quick Changer from OnRobot, any operator can change the end-of-arm tooling on collaborative robots in a few seconds with just a click.

How to Increase Uptime in Press Shops

Here are some of the ways that next generation lightweight tooling systems and new tooling components are optimizing stamping process safety, speed, uptime, cost and standardization, creating more efficient and reliable operations to satisfy stringent production demands.