Filler Metals/Electrodes

Filter by Process Zone:

Forney Industries Retains Creeden for Sales Support

This deal will almost double Forney’s national sales force of 60 people.

Field vs. Shop: What’s the Best Welding Process for Structural Steel Fabrication?

Whether structural steel welding is taking place in an indoor shop setting or outdoors in the field is a factor that either introduces or eliminates a host of elements, including wind, the enemy of shielding gas and the welding processes that rely on it. Here are some insights to help you choose the right structural steel fabrication process for a field application or for shop welding.

Lincoln Electric Partners with SmartEquip Network

SmartEquip now provides owners of Lincoln Electric welding equipment with product information and parts support catalogs to maintain their fleet.

Tips for Successful Aluminum MIG Welding Repairs

With its low melting point, the presence of an oxide layer on its surface, prone to burn-through with a difficult-to-control weld pool, aluminum can be somewhat tricky. Here are some insights that will provide you with the best course of action to take for making a repair.

Miller Electric and Hobart Brothers Earn Stringent Quality Certification

Both companies are registered to ISO 9001:2015 for sharing organizational knowledge, risk assessment, top management leadership and improvements.

Reduce Moisture-Absorption and Cracking Risks with Seamless Wires

Not every welding application requires the benefits that higher priced seamless wires provide. But when moisture must be controlled to help minimize the risk of hydrogen-induced cracking in demanding high-strength applications – and with it, costly repairs or potentially catastrophic weld failures – seamless welds are the ideal solution for the job.

Hobart Brothers Celebrates 100th Anniversary

A rich legacy of welding innovation was celebrated by more than 500 current and retired employees, friends and corporate partners, customers and business colleagues, and local city officials.

The Growing Need for Stainless Steel Filler Metals

The comprehensive stainless steel filler metals line from Hobart Brothers has expanded to include stick electrodes and metal-cored wires by adding options in solid wire and flux-cored wire.

IWDC Spending Sets New Record

The spending of Independent Welding Distributors Cooperative member companies through their co-op exceeded $19 million in March.

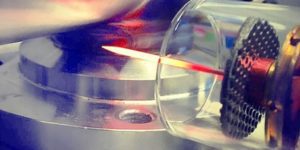

Successful Gas Tungsten Arc Welding

Unlike the red-tipped thoriated tungsten electrode that contains two percent thoria, blue-tipped MultiStrike tungsten electrodes from Huntingdon Fusion Techniques HFT contain a mix of non-radioactive rare earth elements, eliminating the risk to health posed by thoriated tungsten electrodes.

Understanding Stainless Steel Filler Metals

The properties of stainless steel offer corrosion resistance, toughness and strength, a good appearance and longer useful life. But there are some challenges when welding stainless steel. Consider these tips and best practices, including proper filler metal selection, to get the most from stainless steel welding applications.

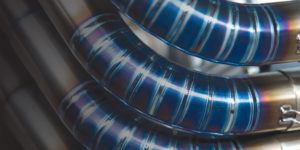

How Submerged Arc Welding Can Improve Productivity

Ideal for demanding applications in pipe, pressure vessel and tank, railcar manufacturing and heavy construction/mining, this process offers great benefits in its simplest form of single wire welding, plus more in twin wire, tandem wire and multi-wire SAW configurations.