Grinding Machines

Filter by Process Zone:

Air-Powered Right Angle Grinders and Sanders

The Right Angle Disc Sander and Right Angle Depressed Center Wheel Grinder from Dynabrade are excellent for fast stock removal, metal clean up prior to welding, removal of weld beads and various material removal applications.

Durable Corded Brushless Grinders for Metalworking

The 5 in / 6 in Paddle Switch Small Angle Grinder from DeWALT features a Lanyard Ready integrated lanyard connection point, E-Clutch System, Kickback Brake and Brake that quickly stops the wheel in one second or less when the trigger is released while using 6 in Type 1 cutting wheels.

Fast and Easy Sharpening of Turret Press Tooling, Progressive Dies and Small Die Sets

The PDG Rotary Surface Grinder from DCM Tech has center-mounted rotary fixturing to hold punches and dies up to 6 ¼ in diameter, with fixture enhancements to sharpen dies up to 8 in and punch fixturing that allows sharpening of straight and shear angle punches with up to 10 deg pitch.

Simple, Fast and Precise Sharpening of Tooling

Suitable for all tooling styles, the fully automated XSharp grinder from Wilson Tool provides highly stable bearing properties to ensure optimal precision and an excellent surface finish on sharpened tools.

18V Large Angle Grinder for Tough Heavy Steel Fabrication Jobs

Using a new brushless motor for speed and capacity without bogging down, the M18 Fuel 7 in/9 in Large Angle Grinder from Milwaukee Tool features exclusive electronics that ensure maximum tool performance under load without overload and overheat, and a battery that exceeds higher voltage systems.

United Grinding has New Owners

Investors at Swiss BZ Bank Aktiengesellschaft purchase the company from Körber AG.

Bourn & Koch Expands Distributor Network

Five new distributors will help increase their sales and support across the Midwest, West, Northwest U.S. and Alberta, Canada.

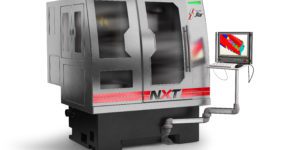

Next Generation Tool Grinding and Advanced Gear Hobbing

The compact NXT CNC 5-axis tool grinder and the FFG Werke Modul H 80-200 vertical gear hobbing machine from Star SU are suited for automotive as well as job shop applications.

Seco Machine Announces Plans for New Plant

This larger $8 million plant will meet growing demand for their contract machining services and custom-molded urethane parts.

Grinding, Milling and Drilling in a Single Part Clamping

With spindle speeds up to 10,000 rpm for high precision machining, the 5- or 6-axis Mägerle MFP 51 grinding and machining center from United Grinding combines grinding, milling and drilling in a single part clamping to dramatically improve productivity.

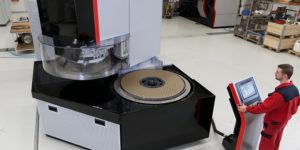

Batch Mode Fine-Grinding Systems

The Spiro F5 and Spiro F12 from Supfina can grind highly precise, ≤ 1.0 µm plane parallelism and machine precision bearings, pump gears, valve plates, and more up to 20 times faster than lapping to greatly reduce costs per unit.

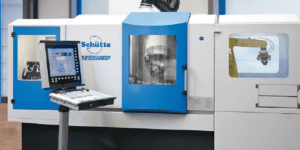

Flexible Grinding of Micro Tools, Gun Drills, Hob Cutters and Complex Geometries

Along with advanced wheel changing, automated collet changing and robotic workpiece handling, the flexible 325linear 5-axis CNC grinder from Schütte is equipped with SIGSpro software for full 3D simulation on the HMI or offline for more accurate quotes and complete cycle validation.