Horizontal Machining Centers

Filter by Process Zone:

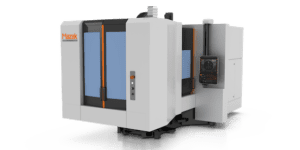

Next Gen Horizontal Machining Center Expands Range of Applications

Mazak’s HCN-6800 NEO comes with upgraded standard features and numerous options, too. Its cycle times are faster, its footprint is smaller, and its range of part and tool capacities are wider.

Nitrogen Generation, Gas Mixing Products Reduce Costs and Floor Space

Bystronic Inc. and MSS Nitrogen Inc. partner to sell Bystronic’s Nitrocube nitrogen generation and NitrO2 gas mixing products, powered by MSS, in the North America market. Nitrocube’s nitrogen purity is 99.999%, while NitrO2 mixing can triple laser cutting speeds.

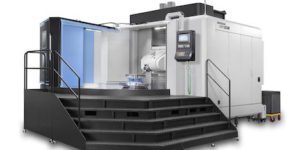

VERY Heavy-Duty Horizontal Machining Center (HMC)

Ideal for the demanding aircraft, automobile, power generator, mold-and-die, and semiconductor industries, Niigata’s 5-axis HN80E-5X horizontal machining center (HMC) produces 1.65-ton parts almost 50 inches in diameter and 40 inches high.

Machine and Turn 2-Ton Workpieces in A Single Setup

Doosan’s DHF 8000ST is a single-table version of the company’s DHF 8000 5-axis horizontal machining center (HMC) that incorporates a turning function so manufacturers can save time by moving from roughing to finishing with one setup.

Match Spindle Performance to Specific Machining Need

Suitable for high-volume large, heavy part operations, Mazak’s HCN-5000 is a horizontal machining center that offers users the option of high-speed or high-torque integral motor spindle, so they can align proper speed and power for the job at hand.

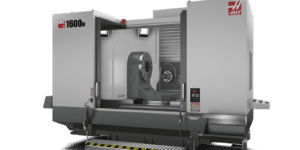

5-Axis Universal Machining Center

Haas Automation’s UMC-1600-H provides the 50-taper cutting, heavy-duty rotary axes, and large work envelope required to machine large parts for customers in the oil-and-gas, alternative energy, and other heavy industries.

Easy-to-Use Horizontal Machining Center for Numerous Applications

Mazak’s HC-5000 4-axis horizontal machining center (HMC) boosts speed, output, reliability, and precision of numerous metalworking applications in nearly any production environment. Easy-to-program controls automatically calculate intersection coordinates and tool index positioning to optimize cutting.

Configure a New Application for Your Horizontal Machining Center

KME CNC 5-axis tombstones and trunnions and 4- or 5-axis rotary tables turn 3- axis and 4-axis machining centers into 5-axis production machines. The wireless KME TS630 tombstone transforms horizontal machining centers (HMC) into 5-axis machines that operate lights-out for eight hours at a time.

IBAG North America Offers Factory-Certified Spindle Repair

High utilization rates can hinder machine tool performance. High-speed spindle manufacturer IBAG North America provides uptime by offering repair services including condition evaluation, internal-parts analysis, and rebuilding from its North Haven, Conn., facility.

Samag Machining Centers and Deep Drilling Machines Available in North America

German Machine Tools of America (GMTA) is selling the full line of Samag MFZ Series multispindle machines for high-volume cubic workpieces. Applications include knuckles, engine blocks, gear boxes, valves, and connecting rods for the automotive powertrain, truck, and off-highway markets.

NADCAP-Certified Job Shop Sets a Course for Automation

New York-based Globe Grinding faces the same skilled-workforce gap as other manufacturers. To meet the requirements of demanding aerospace customers, the company is deploying technology current employees can easily learn to program and operate.

Methods Machine Tools Tapped to Distribute OKK Machining Centers

Known for power, speed and ease of maintenance, OKK’s horizontal, vertical, and 5-axis machines are now being sold and serviced throughout North America by Methods Machine Tools based in Massachusetts. To control quality, OKK manufactures its key machine tool components in-house, including spindles, mechanical gears, precision square slide guide ways and special controller features.