Horizontal Machining Centers

Filter by Process Zone:

New HMC Helps AME Grow Business

Their Toyoda FH800SX-i horizontal machining center helps increase business by 25 percent in tombstones, custom fixtures, and workholding components.

Flexible 5-Axis HMC For High Productivity and Absolute Precision

The FP 4000 5-axis horizontal machining center from Heller Machine Tools uses twin drives in the Z axis for heavy duty cutting, combined milling and drilling operations, or 5-sided machining in a single setup for contract manufacturing or tool and die work where 5-axis milling is needed for productivity and process dependability.

Innovative, Compact HMC With Column Traverse Structure

The KIWA-Japan Triple H40 Horizontal Machining Center with a Column Traverse Structure from Methods Machine Tools supports the flexible mounting of various fixtures and rotary tables based on the application.

Large Part Precision Machining Services

Coldwater Machine Company performs precision machining with tolerances of +.0003 in for prototype creation or contract manufacturing of large jigs, fixtures, lift devices and material handling equipment for the energy industry made from a variety of materials.

Quill Spindle HMC Produces Large, High Precision Bores for Energy Applications

The HU100 Quill Spindle horizontal machining center from Mitsui Seiki USA is well suited for boring of gas field valves and fittings, in addition to other fluid transfer components up to 60 in diameter and weighing up to 6,600 lb.

5-Axis Machining of Gas Turbine Blades for Power Generation

The LX 251 from Starrag performs efficient, complete five-axis machining of complex, high-tech turbine blades in one clamping for consistent reproducibility of workpieces that is critical when manufacturing fan blades.

Haas Automation Reports Record Sales

They sold more than 13,500

machine tools in 2017, an increase of nearly 30 percent over the previous year.

Mazak Names New General Manager for Northeast Region

Jim Rutan now oversees sales, service and applications support in New England and the eastern halves of New York and Pennsylvania.

Matsuura Machinery Expands Territory for Yamazen

Yamazen now represents Matsuura machine tools in 24 states, including a new “Yamazen South Region.”

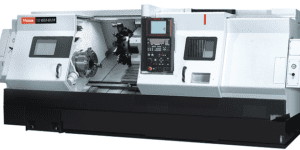

Multi-Tasking Productivity in Machining Large Parts for Oil and Gas

The multi-tasking QTN 450M turning center from Mazak performs milling, drilling and tapping operations for highly efficient single-setup part processing to boost productivity and reduce cycle times when machining large diameter, shaft-type parts used in oil and gas.

Superior Machining of Large, Complex Parts for Oil and Gas Machinery

Using superior vibration absorption for improved part surface quality and finish, the Mycenter-HX800G horizontal machining center from Kitamura Machinery delivers the high precision, accuracy and repeatability required for producing close tolerance parts from the toughest of materials.

Effective Machining of Long Pipes and Rods for Offshore Plants and Oil Exploration

The PUMA 1000/M from Doosan boasts the strongest cutting capacity in its class, has a maximum machining diameter of 39 in and a maximum machining length of 80 in, and provides a wide spindle through-hole of up to 22 in for processing long pipes and rods.