In-Line Process Monitoring

Filter by Process Zone:

Fives Partners with NRC Canada

They are developing a new profilometer for faster, more accurate part inspection of composite structures used in aerospace manufacturing.

Hexagon Acquires Etalon

This deal expands their footprint in calibration systems and on-machine measurement systems.

No Touch, Just Inspect and Go

Every time a part is touched adds cost to it. To reduce costs, improve the measurement process and optimize cycle time, here are some of the newest metrology systems, controls and tools that enable shops to inspect parts and tools and monitor machines without any unloading, reloading, repositioning or transfer of parts to a measurement station or lab.

Visual Inspection of Root Pass Weld Bead Inside a Welded Pipe

Serimax uses Xiris visual inspection and laser measurement technology in the orbital welding of offshore oil and gas pipes.

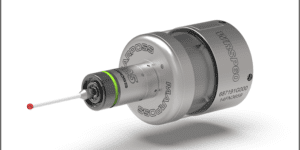

Compact, Highly Repeatable Radio Probe for Small 5-Axis Machine Tools

The ultra-compact RMP400 strain gauge probe from Renishaw delivers reliable, precise touch-trigger part setting, feature measurement and machine performance checking.

Compact Precision Laser Measurement Sensor for Real-World Targets

For precise part inspection, assembly and accuracy checks, dimensional control, product position control, correct product placement, thickness measurement and more, the LM Series laser measurement sensor from Banner Engineering works best in conditions that can cause measurement error.

Radio Transmission Scanning Probe for Real-Time On-Machine Part Measurement

The WRSP60 high accuracy scanning probe from Marposs checks part profiles, misalignment, surface deformation, runout and more directly on machining centers and milling machines in real-time without any handling to improve the process and optimize cycle time.

In-Line Measurement of Mid-To-Large Sized Parts

The versatile 360 deg FMC-Tracker flexible measurement cell from Hexagon delivers a new level of automated measurement productivity that can easily scale to the appropriate size for any workpiece and measure multiple parts in production.

In-Process Tool Measurement in Machine Tools

The LC50-DIGILOG laser measuring system from Blum-Novotest shortens tool measurement and testing times up to 60 percent using an optimized beam shape and 30 percent smaller focus diameter for better absolute accuracy.

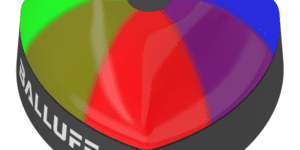

Point-Of-Use Indicators Increase Responsiveness, Repeatability and Reliability

SmartLight visual indicators from Balluff can direct, instruct and guide operators in nearly any manufacturing task to increase productivity and minimize workforce errors by providing innovative personnel guidance in pick-to-light systems, part placement, part positions, format change guidance and many other applications.

AMETEK Surface Vision Names New Vice President

Jason Zyglis is now their divisional vice president of project and product management.

Visual Indicator Delivers Operator Guidance at Most Critical Point

SmartLight indicators from Balluff can direct, instruct and guide operators in nearly any manufacturing task to increase productivity and minimize workforce errors.