Ironworkers

Filter by Process Zone:

Advanced Metalworking Equipment to Increase the Bottom Line

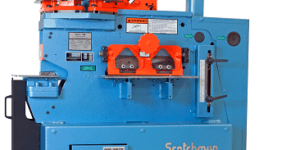

For processing heavy materials, structural profiles, non-ferrous material and more, the latest hydraulic ironworkers and sawing systems from Scotchman provide the flexibility and precision needed for high productivity on tough jobs.

Economical Ironworkers and Punch Presses for Full Fabrication of Standard and Custom Jobs

The two-cylinder/two-person operation of the MM Series Complete Five-Station Fabrication Center from Kalamazoo Metal Muncher allows the punch and shear end to be operated separately, independently and simultaneously at full capacity and speed. Their GB Series Hydraulic Punch Press can also be fitted with special tooling to allow shearing or forming.

AHB Tooling & Machinery Acquires Division of Westbrook Engineering

Adding the new machinery sales division reinforces their position as a full-service metalworking distributor.

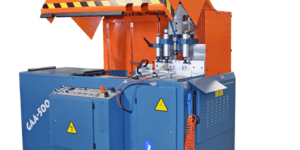

Automated Sawing Systems and Versatile Ironworkers

For the most effective fabrication operations, Scotchman offers a complete line of hydraulic ironworkers, circular cold saws, band saws, tube and pipe notcher/grinders, manual measuring systems and programmable feed and stop system.

U.S. Machine Tool Orders Accelerate

June manufacturing technology orders climbed 6.5 percent over May to $373.2 million.

Punch Heavy Plates Instead of Drilling or Burning Them

The Geka Hydracrop 220 SD ironworker from COMEQ uses a semi-automatic gauging system and a punch capacity of over 240 tons to punch up to 1-9/16 in diameter holes thru 1-1/2 in thick A36 steel plate so that users can now punch heavy plates that would normally require drilling or burning.

KBC Tools Granted National Women’s Business Enterprise Certification

They are granted certification by the Great Lakes Women’s Business Council.

Scotchman Announces Golden Anniversary Giveaway

To help celebrate their 50th anniversary, they are holding a sweepstakes drawing to give away a new 50 ton ironworker to a school shop class.

Sheariously Awesome Ironworker Automation

Automating the shear section of an ironworker with a simple stop and some software is a relatively easy way to reduce cycle times on both shearing and setup and improve part accuracy, eliminate rework, and improve material yield.

FABTECH 2016: Forming & Fabricating

Take a closer look at some of the metal forming and fabrication technologies that will be exhibited November 16-18 on the show floor in Las Vegas.

Innovative Caliper Set, Automating Ironworker Operations

The TigerSPC caliper set from TigerStop easily measures parts up to 16 ft.

Versatile Ironworkers, Saws

New ironworkers, a new vertical tilt-frame and a horizontal mitering saw from Marvel Manufacturing improve operating productivity and part quality.