Laser Cutting Systems

Filter by Process Zone:

CO2 Lenses and Mirrors for Precision Laser Engraving of Medical and Dental Instruments

CO2 Precision Marking Lenses from Laser Research Optics come in 0.5 in to 1.5 in sizes with focal lengths from 1 in to 25 in at 0.5 in increments with < 0.2 percent total absorption values to keep them cooler.

Jenoptik Appoints New Director

Robin Swain is now the senior director of their Silicon Valley Application Center.

MC Machinery Systems Appoints New Distributor

Black Rock Machinery is their new distributor of Mitsubishi Laser in Kansas and Missouri.

Bystronic Breaks Ground for Experience Center

This new “smart factory” for sheet metal processing will be completed by the summer of 2019.

Sheet Metal Marking Review

Demands are growing for sheet metal fabricators to mark their parts during production for product traceability in the field and better efficiencies in the shop, but many part identification systems can add an unnecessary secondary process. Whenever possible, consider finding ways to incorporate part marking into a manufacturing step that is already required. Here are some ways to use the equipment that you already have.

QUEST Machining & Fabrication Expands Operations

They now provide artistic design services, from concept to creation.

All-Electric Tube Bending of Multiple Radii in a Single Setup

For tube production in HVAC, furniture, automotive, aerospace and other applications, Elect 9-axis all-electric tube benders from BLM Group are suited for tube diameters from 1.5 in to 6.0 in and have multiple tool stack capability that can produce fixed and variable radii in a single setup.

FMS Approach to Industry 4.0 Factory Digitalization

The FlexCell automated kit blanking and short run bending system from Salvagnini combines press brake and panel bending technologies for the fastest, least expensive, most profitable way to form parts.

Ultra-High Purity Nitrogen Gas Generators for Laser Cutting Applications

Nano GEN2 nitrogen gas generators from Nano-Purification Solutions provide operating pressures of 145 psig and 232 psig and boost pressures to 5,000 psig for flow rates with purities from 95 percent to 99.999 percent.

Efficiency-Driven Fiber Laser Cutting, Turret Punch Press Operations

The Muratec LS3015GC fiber laser from Murata Machinery cuts through steel, stainless steel, aluminum, brass, bronze and other ferrous and nonferrous metals, while their Motorum M2044TS turret punch press uses a servo-electric punch drive system that incorporates the latest ram drive design.

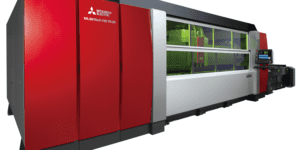

Industry 4.0 Fiber Laser Cutting System

In line with Industry 4.0 real-time process, consumption and service monitoring, the Advanced 800 eX-F fiber laser cutting system from MC Machinery incorporates an all-new M800 control with enhanced industry-leading functionality.

Game-Changing Direct Diode Laser Cutting Technology

The Optiplex 3015 DDL 6 kW direct diode laser cutting system from Mazak Optonics utilizes flying optics, a two-pallet changer and a high performance digital drive package.