Lathes

Filter by Process Zone:

Advanced Vertical Turning Achieves World-Class Precision

Ideal for manufacturing medium and large batch runs, the compact VL 4 Vertical Turning Machine from EMAG utilizes a modular inverted vertical lathe configuration for machining precision metal parts, reducing floor space costs and increasing machine layout flexibility.

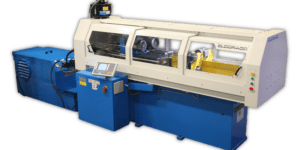

Twin-Spindle Gundrilling Machine with Independent Spindle Control

The Eldorado M30-30T twin-spindle gundrilling machine from Kays Engineering performs two independent precision drilling cycles at the same time.

Comprehensive Turning Software with Powerful Toolpaths and Techniques

From accepting and programming any CAD file to Dynamic roughing and precision finishing, Mastercam 2017 Lathe software from CNC Software gives users a variety of techniques to turn all of their parts exactly as they need them.

Digital Production Management and Cryogenic Machining

Several machine tool builders are demonstrating the shop floor cost savings and production improvements of machining with cryogenic technology and digital production management from 5ME.

Okuma Adds Machine Tool Specialist to Sales Team

Errol Burrell now supports their sales and distribution partners in 5-axis machining applications.

SMTCL Makes Impact with New Vocational Training

Their new programs with high schools provide students with real world skills in manufacturing .

High Speed, High Precision, High Volume Machining

The Giddings & Lewis V 1000 vertical turning center and Hyundai WIA KF5600 vertical machining center from Hillary Machinery are ideal for job shops requiring high metal removal rates and high precision.

Advanced Machining and Measurement Systems

P.D. Browne provides advanced machine tools from Murata Machinery, You Ji, Johnford and Sodick, and innovative CMMs from Aberlink.

Modular Vertical Pick-Up Turning Centers

VL series vertical pick-up turning centers from EMAG are ideal for producing high precision chucked parts that require turning, gear hobbing, chamfering, induction hardening and other special capabilities.

Going Deep: Oil and Gas

As the oil and gas industry explores new technology to innovate, minimize costs, and help contribute to achieving a lower-emissions environment, equipment and parts suppliers must dig deep to find ways to reduce their costs, improve their delivery times and increase component quality. Here are some of the latest machine tools and other equipment that can help them get the job done.

High Precision Cutting in a Small Footprint

With powerful cutting capabilities, a class-leading working range and excellent ergonomics, the V760EX vertical lathe from Okuma is ideal for for machining thin and odd-shaped work pieces used in the oil and gas industry.

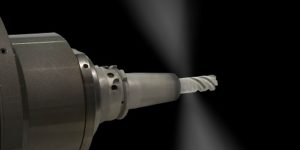

Advanced Deep Hole Drilling Systems

The Okuma MCR-A5CII-35×100 double-column machining center at Unisig is the largest double-column machine of its type in North America, with multiple heads that can process five sides of a large part in a single setup.