Lubricants, Coolants, Metalworking Fluids

Filter by Process Zone:

Lubricants, Coolants, Metalworking Fluids

This category includes substances used in the metalworking process to lubricate, cool, and facilitate the cutting process. Lubricants are used at the interface between a tool’s cutting edge and the chip, preventing the chip from being welded to the tool….

Filter Technology System to Kyocera

Filter Technology selected to design, engineer, and supply a central carbide filtration system.

Anodizer Puts Brakes on Weakest Link

New oil shear brake technology from Force Control Industries eliminates crane downtime and maintenance for this high volume anodizer.

The Brake Stops Here

Built upon the proven oil shear technology, the innovative design of the MagnaShear™ Motor Brake from Force Control Industries is ideal for use on cranes, hoists, winches and other overhead material handling applications because it lasts longer than conventional brakes, and requires virtually no maintenance.

Why Aren’t More Manufacturers Using Minimum Quantity Lubrication?

While the idea of sustainability is becoming better defined and understood, many manufacturers are still not taking the necessary steps to implement newer proven technologies that foster sustainability. Why?

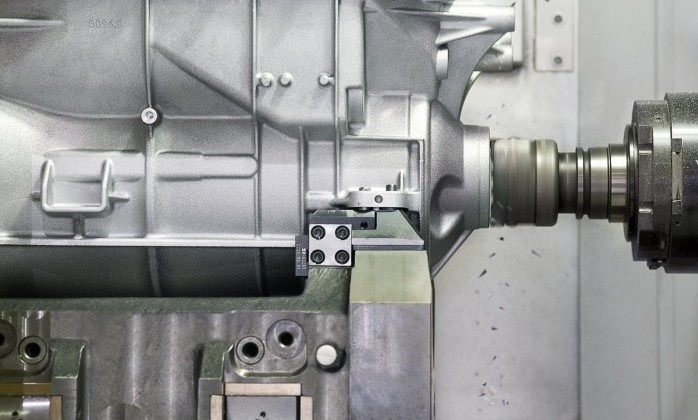

How to Clean Up Cast Iron Machining

This case study explains how Chemtool formulated a novel metalworking fluid with Dow Chemical to clean up the cast iron machining operations of a Midwest machine shop.

WAY OIL AND COOLANT SEPARABILITY

Because they affect both machining precision and the service life of the metalworking fluid, slideway lubricants are integral to the productivity of modern machine shops. Here are some tips from Mobil Industrial Lubricants on selecting the correct slideway lubricants for your application.

PROPER CARE AND MAINTENANCE

Even though a machine tool spindle is a high-precision machine component, more often than not it is handled carelessly, forced to perform well beyond design limitations, or otherwise abused to the breaking point. Ed Zitney of SKF Machine Tool Services shows how proper care and maintenance can make all the difference in both its operation and longevity in service.

CHECK-UP ON PREVENTIVE MAINTENANCE FOR HYDRAULIC PRESSES

Guest columnists Thomas Lavoie and Carl Jean of Greenerd Press & Machine Company explain how, by knowing when a hydraulic press is running well or is in need of attention, and by consistently conducting preventative maintenance, the lifespan of a press can be significantly increased to maximize your investment.