Lubricants, Coolants, Metalworking Fluids

Filter by Process Zone:

168 Manufacturing Debuts Its Automated Coolant Delivery System at IMTS 2022

The FullShop Automated Coolant Management System monitors and replenishes all CNC machine sumps with optimized top-off ratios before the coolant runs low.

Zeller+Gmelin’s Zubora 77 Product Line: Skin-friendly Lubricant for Machining

With a growing portfolio of boric acid-free cooling lubricant alternatives, Zeller+Gmelin is committed to health protection and sustainability.

Unist Saw Blade Lube Systems™

Unist Saw Blade Lube Systems™ deliver all the benefits of Minimum Quantity Lubrication to band or circular saws in a durable, easy-to-install package.

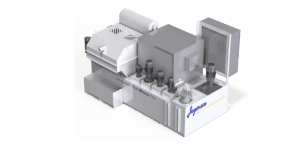

Jorgensen’s New FlexFiltration Line Delivers Simplicity and Value

The systems feature pre-engineered modules that ensure fast, easy and flexible filtration system configurations.

KYZEN’s Tech2Tech Website Features Improved On-demand and Search Features

Each session concentrates on a specific cleaning challenge and specific industry that KYZEN serves globally, including metal finishing.

AMOLEA™ AS-300 Fluorinated Cleaning Solvents Approved by the EPA

The EPA’s Significant New Alternatives Policy program lists these solvents as acceptable for electronics cleaning, metals cleaning, precision cleaning and coating diluents.

The Squeaky Wheel Gets the (Biobased) Oil!

When tested according to the ASTM D-3233 Falex Pin and Vee Block Test, which demonstrates the extreme pressure properties of lubricants, EcoLine® ELP was able to hold up under a much heavier load than the other lubricants while avoiding scarring.

Boost Your Parts Cleaning and Corrosion Control Processes

Achieve maximum results when cleaning parts, treating hard-to-reach places, and preparing surfaces for additional applications with the latest technologies in cleaners, coolants and lubricants.

Five Ways Metalworking Fluid Recycling Equipment Delivers ROI

Accurate and precise cutting fluid recycling equipment contributes significantly to reducing your shop’s annual cutting fluid management operations.

The Aston Martin of Blaser Swisslube

In 2021, the long-awaited Bond film “No Time to Die” finally arrived in cinemas. Together with the Bond films, the Aston Martin, too, has acquired cult status. Reason enough to pro-duce an Aston Martin in the Blaser Technology Center with minimum quantity lubrication (MQL), thought Christoph Fankhauser, Product Manager, Neat Oils at Blaser. The car has also been equipped with headlight nozzles – special effects included.

Up Your Game with Reliable and Safe Cleaning and Lubrication Products

Fabricators can attain spotless and unsoiled parts and machinery in an environmentally responsible way.

Five Ways to Improve ROI with the Right Maintenance Products

Reduce machine downtime and improve efficiencies by using products designed to tackle the most demanding maintenance challenges.