Machining

Filter by Process Zone:

Seco Machine Announces Plans for New Plant

This larger $8 million plant will meet growing demand for their contract machining services and custom-molded urethane parts.

High Volume Gundrilling of Scroll Compressor Drive Shafts

The DeHoff 518 Cell from Kays Engineering uses nine gundrilling spindles to drill opposing holes in balanced throughput: three on a single machine base for the larger diameter shorter hole, and six others on two separate machine bases for the smaller diameter deeper hole.

Hutchinson Manufacturing Executive Receives Award

Company president Tom Daggett is honored with the 2018 Made in Minnesota Manufacturing Awards Lifetime Achievement Award.

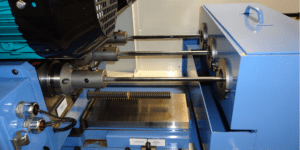

Turning Centers for Heavy, Chatter-Free Cutting and Improved Part Finish

Ideal for jet engine builders machining hard aerospace alloys, the V 1600 mid-range vertical lathe from Fives Giddings & Lewis incorporates a hydrostatic ram to maximize rigidity and a programmable infinitely-adjustable cross rail positioning axis that allows shops to minimize ram extension.

Automation Systems for Economic Small Batch Production

To automate high mix, low volume production operations, Fastems offers the FMS ONE fully configurable machine tool pallet system, Manufacturing Management Software with extended capabilities for controlling robotics, and the Halter Load Assistant compact loading robot cell.

Flexible Horizontal Machining for Small to Mid-Size Parts

The GE40H horizontal machining center from Enshu is perfect for secondary operations and die cast processing, with 19.7 in XYZ-axis travels and full 4th (B) axis that provide great flexibility for small to mid-size parts machining as a standalone machine or as multiples in lean line production.

Immediate High Productivity Machining of Diverse and Complex Shapes

Lynx 2100LY compact turning centers with Y-axis from Doosan come fully loaded with both static and live tool holders, a toolsetter, a parts catcher and a parts conveyor to make machining diverse and complex shapes up to 11.8 in diameter and 20 in long faster and easier with one set up.

Plug-and-Play Robotic Manufacturing Cells Increase Productivity, Lower Costs

Dual-spindle BA 222 or BA WO2-22 machining centers integrated with a 6-axis robot from SW North America provide high speed machining of complex parts made of non-magnetic materials, watchmaking components, automotive impellers and other precision engineering work.

Unmanned Horizontal Manufacturing Cell for Fast-Paced Machining of Complex Parts

Using a a 20-station APC with work ID system, Automatic Work Handling Robot and 174-tool matrix-style tool changer, the SUPERCELL-300G 5-axis horizontal flexible manufacturing cell from Kitamura Machinery is a space-saving production center that can run small to medium sized, highly complex parts completely unmanned.

Intelligent Systems for Process Optimization

SmartMONITOR for manufacturing and AndonSPEED for the warehouse are process optimization systems from WERMA that reduce disruptions and downtime during operations.

IMTS 2018 Showtime: EDM

From CNC wire EDM equipment to die sinking machines, this reliable, high accuracy technology is ideal for tool and die applications, especially shops doing one-off or specialty components.

Faster Wire EDM Cutting with Higher Accuracy, Repeatability and Surface Finish

The AccuteX AL-600SA CNC wire EDM machine from Absolute Machine Tools achieves ±0.00012 in accuracy, ±0.00008 in repeatability, and surface finishes down to 5 Ra µin in five passes.