Machining

Filter by Process Zone:

Industry 4.0 Swiss-Style Lathes are Dynamic, Faster, More Productive

TRAUB TNL18 series Swiss-style automatic lathes from INDEX use an enhanced CNC control, axis amplifier and dynamic drives for accelerations up to 25 percent faster and top speeds that can reduce turning, drilling and milling cycle times on complex parts by up to 21 percent.

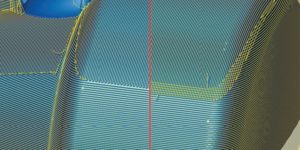

Increasing CAM Functionality and Virtual Machining Simulation

In hyperMILL 2018.1 CAM software from OPEN MIND Technologies, the Soft Overlap function results in better surface quality in transition regions, and Global Fitting offers fast creation of a single face with a defined ISO orientation to prepare for NC programming.

Machining Software for Programmable Class 5 Smartmotor

The AniCNC software system from Moog Animatics provides a graphical HMI, G-code editing and runtime environment, and other built-in features to tackle milling, routing, machining, shaping and related projects with their Class 5 SmartMotor.

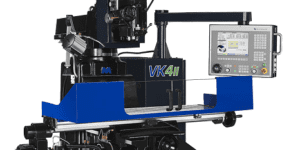

When Sophisticated Multi-Axis Machines are Overkill for the Job

With its unique, programmable MillSlide Z-axis that provides greater rigidity and can also be operated manually with a quill handle, the VK4II CNC knee mill from Milltronics combines the latest knee mill technology with true 3-axis control that can be run as manual, teach or full CNC.

Cloud-Based CAM for Onshape CAD on Any Device, Anytime, Anywhere

MecSoft offers a free public Beta program of their cloud-hosted, fully integrated VisualCAMc add-on app with 2½-axis and 3-axis milling manufacturing capabilities for users of Onshape CAD software.

Readers Support U.S. Tariffs on Steel and Aluminum

54 percent of F&M readers agree with implementing the tariffs, 46 percent disagree.

EDM Monitoring Control for Industry 4.0

The processable data available with the M800 EDM control included in Mitsubishi wire EDM machines from MC Machinery Systems ensures transparency in all production stages, increasing productivity and helping to keep track of production jobs.

Fagor Automation Collaborates with IMH

They are partnering to improve training that is tailored to market needs and to collaborate on technological projects involving machine tools.

Programming and Metal Removal Integrated with Automation and Data Collection

To keep shops productive, efficient and competitive, the dynamic and innovative Smooth Technology platform from Mazak integrates the entire part production landscape, from programming and metal removal to automation and data collection.

Integrated CAM and Tooling Data System Saves Time, Reduces Errors

Mastercam users can quickly import tool assemblies from WIDIA NOVO directly into Mastercam 2018, validate and save them in their file and/or Tool Library, and use features such as automated filtering to ensure that holders and tools selected for a particular job can work together.

Flexible Next Generation Gear Hobbing

The LC 280 α gear hobbing machine from Liebherr offers shops the unique opportunity to machine gears and shafts with a workpiece diameter up to 280 mm and a shaft length up to 500 mm, the range of the most typical machining sizes required for a gear.

Gun Barrel Drilling and Reaming on One Machine

The twin-spindle DeHoff G560-DR2 machine from Kays Engineering has a drilling capacity of 17 caliber to 50 caliber with a slide travel of 60 in and performs both gundrilling and reaming operations on gun barrels.