Machining

Filter by Process Zone:

Drill Press with Hybrid Mill Function

The 3MT Spindle and ER32 Collet System on the NOVA Vulcan Metal Working Drill Press from Teknatool combine for maximum holding flexibility, while its machine tool spindle-specified double-row angular contact bearings deliver rigidity for the side thrust pressures of milling.

Powerful Next Generation Vertical Grinders for Oil and Gas Applications

CP3330 and CP3340 series industrial vertical grinders from Chicago Pneumatic can remove material twice as fast when contouring, deburring, cutting, finishing and weld cleaning cast iron, steel, stainless steel, aluminum, composite, magnesium and titanium.

Grinders for Difficult Applications in Limited Space on Oil and Gas Platforms

Lightweight FA-20 series 2 in angle grinders and die grinders from Fuji Air Tools feature a distinctive low profile grinding head design that is particularly suited to metal grinding for mold maintenance, weld bead removal, deburring and chamfering on oil and gas platforms and in other metalworking applications.

Efficient Turning and Milling of Large Gear Rings and Other Oil and Gas Components

With a spindle design that uses flexible feeds and speeds to cut a variety of materials with excellent surface finish and impressive metal removal rates, the LB3000 EX-II CNC horizontal lathe from Okuma can efficiently turn and mill pipe-type parts with a through-hole diameter that accommodates larger parts.

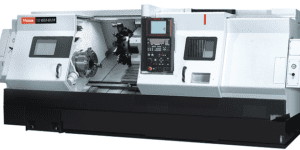

Multi-Tasking Productivity in Machining Large Parts for Oil and Gas

The multi-tasking QTN 450M turning center from Mazak performs milling, drilling and tapping operations for highly efficient single-setup part processing to boost productivity and reduce cycle times when machining large diameter, shaft-type parts used in oil and gas.

ITA Establishes Scholarship Program

This program assists students majoring in related engineering or technology fields of study.

Superior Machining of Large, Complex Parts for Oil and Gas Machinery

Using superior vibration absorption for improved part surface quality and finish, the Mycenter-HX800G horizontal machining center from Kitamura Machinery delivers the high precision, accuracy and repeatability required for producing close tolerance parts from the toughest of materials.

5ME Launches New Website

Their Freedom Smart Manufacturing Platform site features an ROI calculator, details on six smart manufacturing modules, case studies and a free trial offer.

Effective Machining of Long Pipes and Rods for Offshore Plants and Oil Exploration

The PUMA 1000/M from Doosan boasts the strongest cutting capacity in its class, has a maximum machining diameter of 39 in and a maximum machining length of 80 in, and provides a wide spindle through-hole of up to 22 in for processing long pipes and rods.

Toyota-Mazda Announce Alabama Factory

Their new $1.6 billion joint venture in Huntsville will eventually produce 300,000 vehicles a year and employ 4,000 people.

U.S. Machine Tool Orders Climb

Orders rose to $426 million in November, up 19 percent over the previous year.

How to Increase Material Removal Efficiency and Your Bottom Line

From foundries to fabrication shops and final finishing, all areas of metalworking are looking to increase profitability through process efficiencies. Pneumatic tools that are appropriate for material removal can enable users to improve their productivity significantly. Here is a review of the latest air tools and how they are best suited to particular applications, along with considerations to take when specifying tools.