Machining

Filter by Process Zone:

Gene Haas Foundation Invests Big in Workforce Initiative

A $50,000 investment in the “Be Pro Be Proud” initiative in Arkansas showcases to students the many career opportunities available within technical professions in the state.

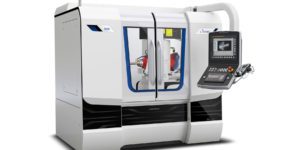

A Wide Range of Advanced Machining Technologies

GF Machining Solutions will display their new AgieCharmilles CUT 2000 X advanced wire EDM, full 5-axis additions within the Mikron MILL S and X product line, advanced automation systems, additive manufacturing, System 3R automated laser texturing, and die sinking and wire EDM machine technologies that target the aerospace, medical and die/mold industries.

Efficient Five-Axis Machining Begins at the Core

The FA1050 5-Axis horizontal machining center from Toyoda Machinery provides competitive boring, end milling, finish cutting, threading and U-axis machining on difficult materials such as Hastelloy, Inconel, Nichrome and other exotic metals.

ITAMCO Receives Award for Smart Manufacturing Project

The project is connecting and configuring diverse machine tools, PLCs, sensors and devices to build a totally integrated shop floor.

IMTS 2016 Sneak Peek: Controls & CAD-CAM

Here is a sneak peek of some of the digitally-enabled tools that will be exhibited on the show floor to help define Smart Manufacturing, the Industrial Internet of Things, Industry 4.0 and other advancements in the digital enterprise.

Mastercam Sponsors Oracle Team USA in America’s Cup

The CAD/CAM software is used to produce carbon fiber composite components for the team’s racing yachts.

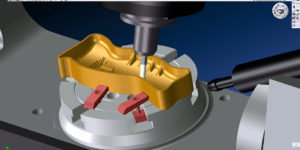

CAM Software Improves Efficiency, Speed, Accuracy of Production Machining

3D Systems will display GibbsCAM 2016 software for production machining from that builds on revolutionary Universal Kinematic Machine technology for solid modeling, high speed machining, 2-axis to 5-axis milling, wire EDM, multi-task machining and more.

IMTS 2016 Sneak Peek: Abrasive Machining / Sawing / Finishing

Here is a sneak peek of some of the grinding technology that will be exhibited on the show floor at McCormick Place in Chicago from September 12-17.

Grinder Automation, New Centerless Grinder

GCH Machinery, Total Grinding Solutions and GCH Tool Group will display a remanufactured ID grinder, a new TGS-CL-6020 CNC centerless grinder, and an exclusive CNC two-axis dresser.

Polycrystalline Tool Grinders

FC-200D, FC-300D, FC-500D, and FC-200CNC Polycrystalline Tool Grinders from Rush Machinery are ideal for grinding angles and radii on standard and custom turning and milling inserts, boring tools, milling cutters, grooving tools, reamers, and other special tools.

Exceptional Price/Performance in Universal Internal Cylindrical Grinding

The Studer S121 universal internal cylindrical grinding machine from United Grinding is suited for a wide range of internal grinding applications in the areas of machine tools, drive elements, aerospace, die and mold.

How Accurate Probing Makes Machining More Precise

Probes can shorten cycle time and improve part quality by reducing the opportunity for human error that results in scrap. Here are some tips to help operators use probes to make their machining processes more precise and efficient.