Machining

Filter by Process Zone:

FANUC America Offers Online CNC Training

This education system teaches users to be proficient in programming machining centers, turning centers and parametrics.

WFW Industries Wins Manufacturing Award

Recognition for a strong economical presence and continuous dedication to the San Diego community.

Molycorp Files Plan to Emerge from Bankruptcy

Their dual-track plan envisions either a stand-alone reorganization or sale of assets.

High Power, Lightweight Portable Magnetic Drilling

Hougen showcases the power feed HMD927 portable magnetic drill and the redesigned HMD904 portable magnetic drill.

Thermal Drilling Saves Time and Money

Formdrill will demonstrate the thermal drilling process that results in joints that are as strong or stronger as the equivalent diameter welded nut.

Heavy Machining for Even Heavier Lifting

This heavy duty lathe removes an amazing 600 kg of material from a 1,400 kg solid steel billet in less than 4.5 hours, leaving a finished and fully machined cylinder body weighing only 800 kg.

Karlstadt Machining Doubles in Size

The shop invests in a new Okuma vertical machining center to meet current demand, with plans to add three more machines over the next five years.

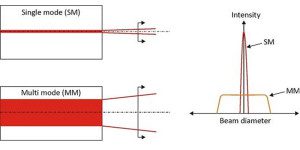

What You Must Know About Single Mode Fiber Laser Markers

The single mode fiber laser marker has best-in-class beam quality that translates to fine marking capabilities plus effective micromachining for drilling, cutting, scribing, ablation for a variety of applications.

Machine Tool 2.0: Milling with Robots

A robot can now replace a machine tool in certain applications, bringing a high level of flexibility to use different tools in the 3D space that changes the way processes and component design are viewed.

Standardized Machine Tool Controls Improve Production of Very Large Parts

This busy shop uses a common CNC platform to address the challenges of machining large parts and one-off runs for power generation equipment.

GE to Build Two Aerospace Manufacturing Plants in Alabama

GE is investing in two massive $200 million aviation manufacturing facilities that will bring 300 jobs to Huntsville.