Machining

Filter by Process Zone:

Manufacturing Enters the Next Information Age

Show Me The Money: With cloud computing starting to generate a lot of noise, Mike Riley sifts through the buzz to explore what all of this really means to manufacturers.

How to Increase Robotic Laser Cutting Path Accuracy

As laser cutting continues to emerge, the programming flexibility of these laser cutting software tools from ABB Robotics take robotic laser cutting to the next level.

Alibre CAM Transitions from 3D Systems to MecSoft

In a move from the rapid prototyping market sector into the small to mid-size machining markets, the fully integrated CAM software running inside the Alibre design family of CAD products is now sold and supported directly by MecSoft.

Hermle Machine Joins CCAM

The newest industry member to the Commonwealth Center for Advanced Manufacturing contributes a precision milling machine and manufacturing expertise to the Center’s collaborative research efforts.

ABB Joins Partners in THINC

CNC machine tool builder Okuma America announces a new member of its collaboration network of industry leaders who come together to solve problems and explore new productivity ideas for manufacturers.

MecSoft Releases New Corporate Blog

The blog covers what’s happening in the CAD/CAM industry by sharing and disseminating pertinent information using a familiar social media platform.

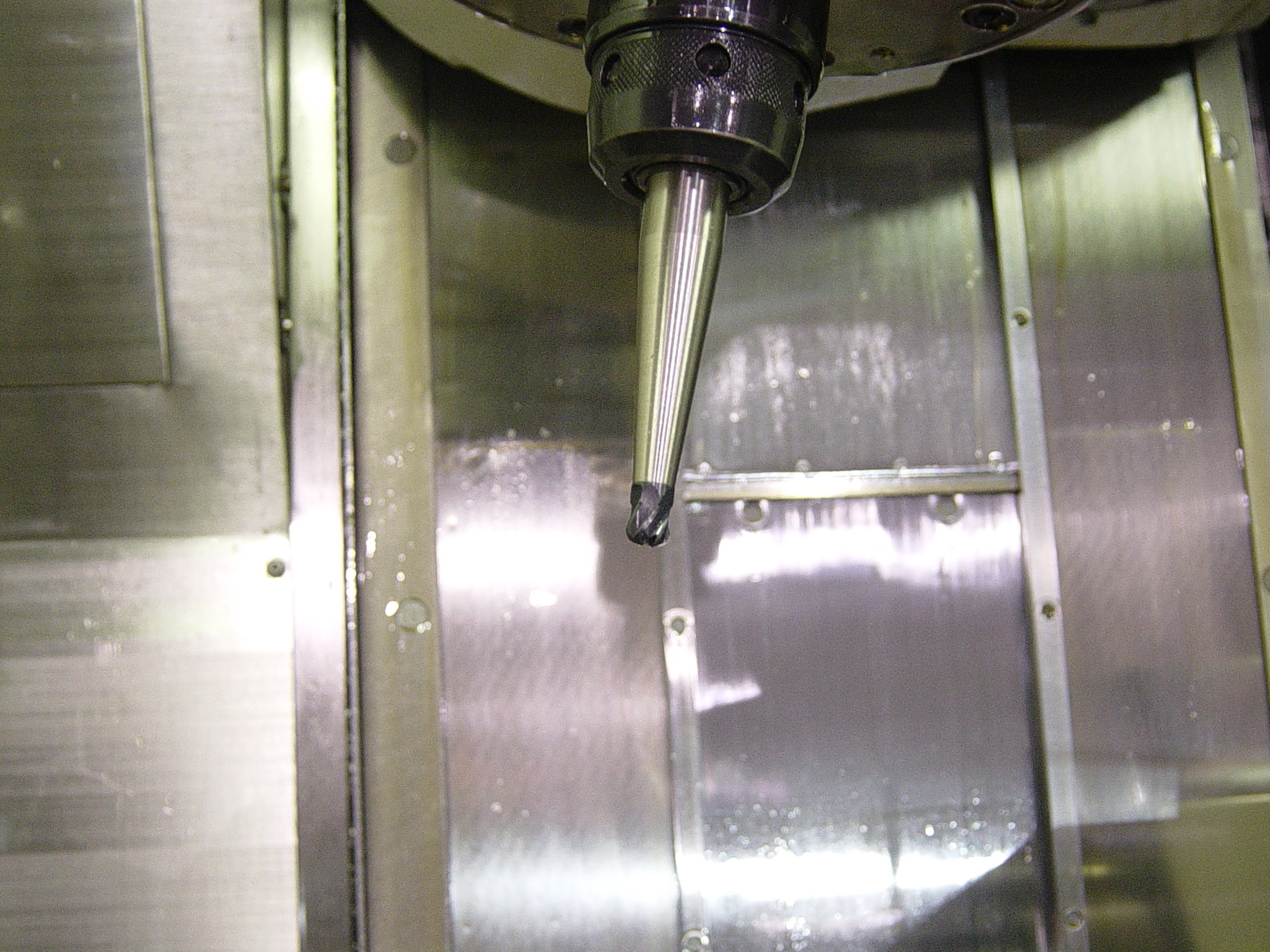

5-Axis Milling with Additional Capabilities

New eVo machining centers from DMG/Mori Seiki are ideal for aerospace, tool and mold making, and medical devices that require simultaneous 5-axis machining, sophisticated ergonomics or integrated mill-turn technology with an integrated pallet changer.

Horizontal Machining Takes Center Stage

The NHX4000 from DMG/Mori Seiki is a heavy-duty horizontal machining center that is ideal for machining workpieces of up to 24.8 in x 35.4 in with a loading capacity up to 880 lb.

How to Automate Composite Wind Turbine Blade Fabrication

These rapid material placement and quick-cure molding systems from MAG combine to reduce lay-up, infusion and curing time by 50 percent while producing consistently high-quality parts.

Multi-Tasking Sharpens Turbine Blade Machining Output

Take It To The Next Level: Combining machining processes and operations inside a single work envelope to improve part quality and reduce labor content in that part is making multi-tasking automation more popular with shops in the turbine blade machining arena.

High Tech Increases Efficiency in Tough Jobs

The MMC-R modular automated robotic fixture-plate system from Makino competes in general machining markets by increasing machine and labor efficiencies when boring and milling tough and hard materials in high product mix, low volume production runs.

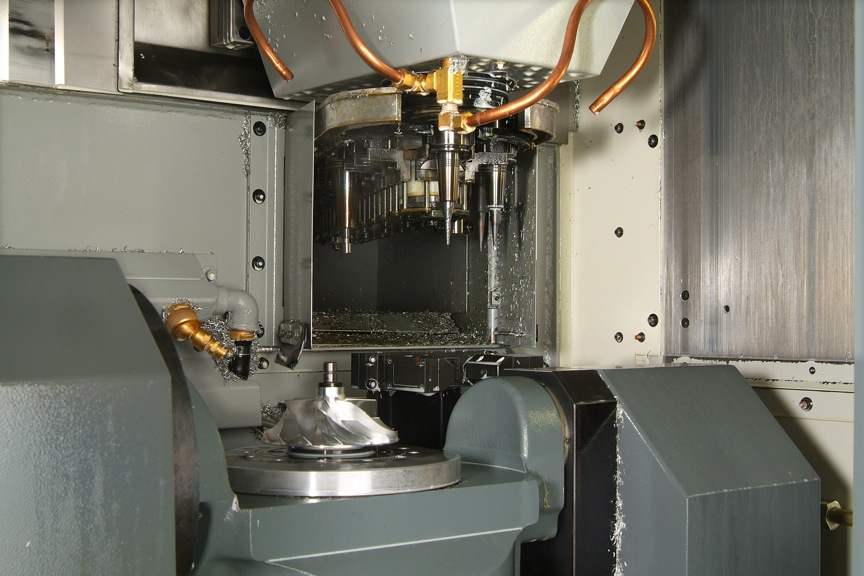

Work Cells Reduce Run Times on Aluminum Impellers by 20 Percent

Turbocam competes in the challenging aerospace, automotive and medical parts markets by using automated work cells with Chiron five-axis machining centers that are equipped with flexible controls from Siemens, open architecture and specialized functions to reduce cycle times and costs in machining and material handling.