Machining

Filter by Process Zone:

THE ROOTS RUN DEEP

Gears from the “potato field”: Modern manufacturing technology, well-founded knowledge and farsighted engagement make source location issues less important.

ELECTROPOLISHING SYSTEM ELIMINATES OUTSOURCING PROBLEMS

A new, compact electropolishing system that offers manufacturers of high-value metallic devices and medical components complete control over all aspects of their production, quality, and delivery schedules is being introduced by METFAB Technologies, Inc.

MASTERCAM'S MULTIMEDIA SECTION ON WEB

CNC Software added new videos to the Multimedia section of the Mastercam.com website, giving customers the opportunity to explore some of the latest features in the Mastercam family with downloadable video demonstrations, narrated overviews, and documents highlighting powerful new tools.

NEW HYBRID LASER CUTTING SYSTEM FOR ECONOMICAL PROCESSING OF LARGE SHEETS

LVD Strippit adds the Orion 4020 to its Orion Series of laser cutting systems. The hybrid-style CO2 laser cutting system is engineered for economical processing of large sheets up to 157 in x 78 in or 4 m x 2 m. Orion laser cutting systems feature a highly rigid, high-precision rack-and-pinion drive system which provides precise motion and position control. This rigid design permits the machine to maintain high processing speeds without loss of cut quality.

KNOWLEDGE BASED MACHINING FOR MEDICAL DEVICE MANUFACTURERS

PartMaker Inc., a division of Delcam Plc, is a leading provider of CAM solutions to six of world’s 10 largest medical device manufacturers (ranked by revenue by Reuters Group Plc), including such companies as Medtronic and Zimmer, Smith & Nephew, Biomet, and Johnson & Johnson. Many contract manufacturers serving the medical device industry rely on PartMaker CAM software to automate the programming of their multi-axis lathes and Swiss-type lathes, which are ideal for manufacturing such medical devices as implantables like bone screws and dental implants and instrumentation for use in surgical procedures.

HIGH PERFORMANCE AUTOMATIC SAWING SYSTEM

Advanced Machine & Engineering Co., Rockford, IL, innovators in sawing technology, announces the AMSAWâ S300, the new addition to their family of carbide sawing systems. The S300 is designed for efficiency, speed and increased productivity for cutting ferrous and non-ferrous materials. It has a capacity of 3.00 in – 12.00 in and utilizes saw blade diameters from 24 in to 36 in. The spindle motor is 60 hp (45 kW) and provided with operator friendly controls. This saw allows for cut lengths up to 30 in and multi-indexing when length exceeds 30 in. Accuracy for length is ±0.005 in.

NEW HYBRID LASER SYSTEM CUTS VARIETY OF MATERIALS

Mazak Optonics Corporation’s new Super Turbo-X Champion hybrid laser cutting system is designed for affordable, high-precision cutting of a wide variety of materials, with easy set-up and operation that has been the hallmark of Mazak lasers for more than 20 years.

CNC ROUTER DESIGNED SPECIFICALLY FOR NESTED-BASED MANUFACTURING

Techno, Inc. introduces the PanelMaster Pro Series CNC Router, designed specifically to meet the demands of nested-based manufacturing. The PanelMaster Pro is constructed of large heavy tubing that is welded and stress-relieved, the perfect foundation for our precision drive system.

CO2 HIGH POWER LASER LENSES MOUNTED INTO FOCUSING LENS HOLDERS

A new service for mounting new CO2 high power laser lenses into customer supplied focusing lens holders used for Amada and similar lasers is being introduced by Laser Research Optics Mounting Service. They specialize in mounting new CO2 high power laser lenses into customer supplied focusing lens holders and assures that the finished assembly will meet pressure requirements.

Fail Safe

What recession? In a medical device market that continues to grow, this Southern California contract machining shop specializes in producing intricate surgical instruments that perform without flaw and without fail.

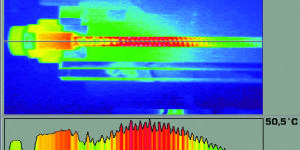

Accuracy of Feed Axes (Part Two)

In the total error budget of a machine tool, the positioning error values of the feed axes play a critical role. The conclusion of this two-part series examines the influence of the temperature distribution along the ballscrew.

Arkansas Contract Machining Shop Zeros in on Auto Aftermarket Product

With the automotive aftermarket industry averaging 4 percent year-to-year growth lately, contract machining shops are finding that aftermarket components can be a lucrative niche . . . . . . such is the case for Service Tool & Fabrication, Inc….